The advantages of plastic slatted floor for poultry for broiler chicken feeding

The plastic slatted floor for poultry are simple and easy, less one-time investment, low incidence of breast cysts and leg diseases, fewer defective chickens, and less pollution to the surrounding environment. The disadvantages are high incidence of coccidiosis and diarrheal diseases, slow growth rate, low feed conversion rate, rising drug and feed costs, and low breeding efficiency, but the incidence of new chicken houses has not changed significantly [3]. In the process of feeding and management, measures such as disinfection, epidemic prevention, coccidiosis and colibacillosis prevention should be strengthened to reduce the incidence rate, improve the survival rate and breeding efficiency.

The advantages of plastic slatted floor for poultry

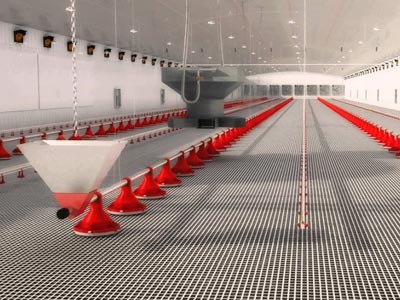

It is convenient for mechanized operation and saves labor; the environment in the chicken house is dry and the air is relatively fresh, which reduces the incidence of respiratory diseases; the temperature around the chicken body is easy to control, which is conducive to growth; The incidence of coccidiosis and intestinal diseases is reduced, and the cost of drugs is low; the survival rate of chickens is high, the growth rate is fast, the feed remuneration is high, and the breeding efficiency is more than 32% higher than that of ground level breeding. The disadvantage is that the one-time investment is large; the incidence of breast cysts and leg diseases is high; chicken manure is difficult to handle, and it is easy to cause certain pollution to the surrounding environment. Farmers must decide the scale of breeding according to their own manure absorption capacity, and cannot blindly expand production. At the same time, rain-proof and seepage-proof dry manure accumulation ponds, sewage sedimentation ponds or biogas ponds should be constructed, and the combination of agriculture and animal husbandry should be done to reduce environmental pollution.

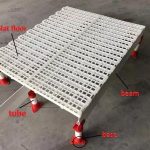

| Base | Made of PVC, the height is adjustable from 280mm to 500mm |

| Beam | Height(material): 9cm(PVC)/12cm(PVC)/15cm(FRP); |

| Length: 3/4 m | |

| Tube | Diameter: 5cm, made of PVC |

When economic conditions permit, farmers can determine the breeding scale according to their own manure absorption capacity, and build a plastic slatted floor for poultry chicken coop at one time, so as to avoid the second transformation of the chicken coop, wasting financial resources, material resources, and manpower. Increased cost input. If the economic conditions do not permit, when the plastic slatted floor for poultry is used to feed broilers, the requirements for feeding and management are higher. It is necessary to strictly control the feeding of chicks, disinfection, and epidemic prevention, so as to reduce the incidence of diseases and increase the income of breeding.