Machines needed to turning Waste into treasure

Chicken Manure Fermentation Tank

The chicken manure fermentation tank is an environmental protection device that utilizes the natural decomposition action of microorganisms. It performs continuous aerobic fermentation in a closed fermentation tank for about seven days, converting chicken manure into bio-organic fertilizer that can be used for crops.

Chicken Manure Disc Granulator

The chicken manure disc granulator is a type of granulating machine that uses high-speed centrifugal force to turn chicken manure and other organic materials into spherical or rod-shaped granules. After drying, the granules can be made into chicken manure balls or pressed into cakes for direct sale, or further fermented into finished fertilizers for sale.

Chicken Manure Compost Turner

The chicken manure compost turner is an ideal device that uses modern technology to convert agricultural waste, livestock manure, and organic household waste into bio-organic fertilizer. Its main function is to turn the material pile after the fermentation temperature rises, ensuring full contact of the fermenting materials with air and increasing the oxygen content of the material pile.

The chicken manure dryer is a drying device specifically designed for the drying treatment of poultry manure such as chicken manure. It is one of the key pieces of equipment in the fertilizer industry.

Chicken Manure Dewatering Machine

The chicken manure dewatering machine is a type of livestock and poultry manure dewatering equipment. It separates raw manure water from poultry manure, such as pig, duck, cow, and chicken manure, into liquid fertilizer for agricultural production systems and solid fertilizer for agricultural production systems.

Chicken Manure Solid-Liquid Separator

The chicken manure solid-liquid separator is a machine used to separate chicken manure into solid and liquid components. It conveys chicken manure into a screw press dewatering machine, achieving solid-liquid separation. The separated dry manure and wet manure can both be effectively utilized. Dry manure is easy to transport and can be used as fertilizer, while wet manure can be applied directly or further processed into biogas for energy.

Chicken Manure Crusher

The chicken manure crusher is a mechanical device designed to crush fermented livestock and poultry manure, urban sludge, pharmaceutical residues, distiller’s grains, and other materials with moisture content between 20% and 50%. It can, for example, crush chicken manure into small particles for further processing and utilization.

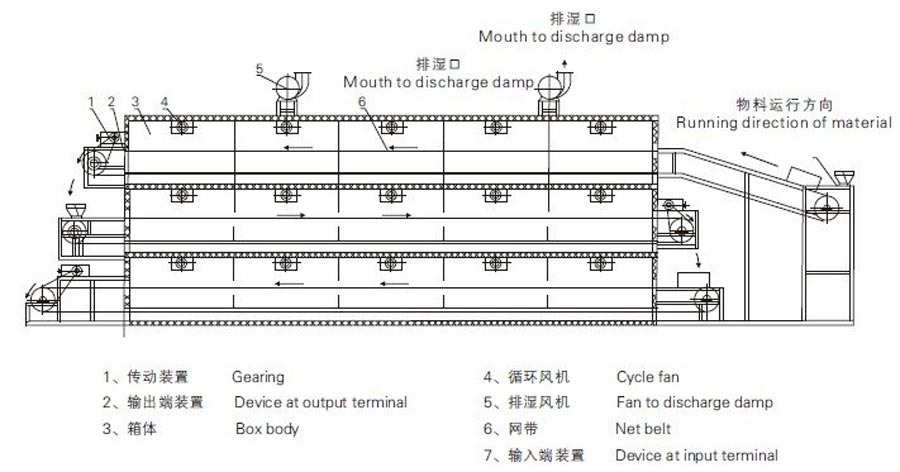

Chicken manure dryer customized for poultry house of all capacity

FamTECH’s chicken manure dryer consists of drying perforated plates, a drive system, electrical control, conveyor belts for wet manure, augers for dry manure, and more. It uses air circulation to remove moisture from the manure, achieving rapid drying (typically around 48 hours). The workflow: fresh manure is conveyed to the top of the dryer → mixed with wet and dry manure in the mixer → evenly spread on the upper drying plate (manure thickness up to 15-18 cm) → driven forward by the drive mechanism to drop gradually to the lower drying plates → collected dry manure is gathered by an auger for remote transportation. The dryer’s dimensions can be customized based on the number of chickens and available installation space. Generally, each square meter of drying plate can dry manure from 400-500 chickens.

Why you need FamTECH’s chicken manure dryer?

The chicken manure dryer features quick installation, high automation, low energy consumption, low failure rate, high stability, and long service life.

Achieves rapid dewatering, reducing the moisture content of fresh manure to ≤29% within 24-48 hours.

Prevents the breeding of pests and diseases in manure, avoiding risks to the environment and human health.

Dried manure is easier to transport and store, reducing transportation and storage costs and saving resources.

Dried manure serves as a high-quality raw material for making organic fertilizers or organic materials.

Emissions from the drying process meet environmental standards, reducing harmful gas exposure to poultry.

Exhaust gas from the dryer is easy to collect and treat centrally.

Chicken Manure Dryer

Dryer Main Structure: Made of hot-dip galvanized profiles, secured with stainless steel bolts, with a height of 1.42 meters and a perforated plate width of 2 meters. It handles manure from 100k-200k laying hens but can be designed and manufactured based on the number of chickens on-site and available space.

Wet Manure Handling: Normally mixed with dry manure and directly enters the main part of the chicken manure dryer. When the dryer malfunctions, or if leaking drinkers cause manure to become too wet, or the processing capacity is insufficient, wet manure is directly removed via a backup cleaning line, bypassing the chicken manure dryer.

Dry Manure Handling: Once dried, manure is directed in two simultaneous directions: one part is mixed again with wet manure via a return auger and re-enters the dryer, while the other part is transported to a designated dry manure storage area.

Air-Drying Principle

Air-Drying Principle: Primarily uses wind to evaporate moisture from the manure, utilizing the heat emitted by the poultry and auxiliary heat from a boiler.

Supporting Civil Engineering Facilities

Site Hardening: Built by the customer, with designs and guidance provided by our company. Due to the heavy weight of the equipment, the ground must have a high load-bearing capacity. The chicken manure dryer area should be hardened with compacted soil and a C30 concrete layer at least 20 cm thick, ensuring a load-bearing capacity of no less than 2t/m², and a ground slope of no more than 2.5‰.

Sun and Rain Shelters: Protective shelters must be built in relevant areas by the customer, with our company providing design drawings and guidance. The shelters should start from the end of the poultry house and cover the chicken manure dryer, dry manure storage, and cleaning line operation areas.

Sealed Chambers: Built by the customer with designs and guidance provided by our company. The main functions include fan installation, air delivery, and partitioning. The chamber must be fully sealed without air leaks and have anti-corrosion properties equivalent to the equipment’s main structure.

Traditional Manure Treatment VS. new type of chicken manure dryer

- Emits waste gases and wastewater, polluting the environment.

- Naturally fermented manure remains soggy, emits foul odors, and cannot fully decompose.

- Fermented manure has high moisture content, making it difficult to store and transport.

- Natural fermentation does not effectively eliminate pathogens, larvae, and other harmful substances in the manure.

- The nutritional content of fermented manure degrades, leading to a lower market price—less than half the price of air-dried manure.

Benefit Analysis of Air-Drying Equipment (Example of 200,000 Laying Hens)

- Daily consumption costs include: electricity, auxiliary materials, maintenance costs, and employee wages.

- Electricity cost is calculated at 0.55 RMB per kWh.

- Employee cost is calculated at 1 person, totaling 200 RMB per day.

- The price of dry chicken manure is calculated at 500 RMB per ton.

- The boiler is only used under conditions such as high temperature and high humidity, or low temperature, to provide auxiliary heating.