Based on the parameters of FamTECH factory’s H-type broiler cages and combined with intensive breeding needs, this design scheme for a closed chicken house accommodating 10,000 broilers is presented below, covering core contents such as cage configuration, layout planning, equipment matching, and structural design.

I. Core Parameter Matching and Cage Configuration

1. Basic Parameter Sorting

| Parameter Item | 3-Tier Cage Specification | 4-Tier Cage Specification | Core Indicator |

|---|---|---|---|

| Total capacity per cage set | 156 birds/set | 208 birds/set | – |

| Dimension of single cage set (L×W×H) | 2230×2150×2550mm | 2880×2150×3200mm | Width is 2150mm (2.15m) for both |

| Cell size | 650×625×430mm (L×W×H) | Same as left | Single cell area: 4062.5cm² |

| Space per chicken | 406.25cm²/bird | Same as left | Meets intensive breeding standards |

| Cell capacity | 9 birds (2kg) / 10 birds (2.5kg) | Same as left | Designed by 10 birds/cell (full load) |

2. Calculation of Cage Quantity

- Core logic: Prioritize 4-tier cages with 10 birds per cell (matching 406.25cm²/bird space) and 208 birds per 4-tier cage set (better space utilization).

- Total demand: The number of cage sets required for 10,000 broilers = 10,000 ÷ 208 ≈ 48.07 sets. Actually, 49 sets of 4-tier cages are adopted (with a redundancy of 56 birds to avoid overcrowding).

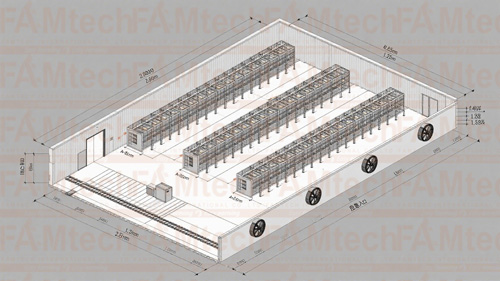

II. Chicken House Layout Planning

1. Cage Arrangement Design

Adopt double-row parallel arrangement (mainstream efficient layout in the industry), as follows:

- Number of rows: 2 rows (reducing channel occupation and improving space efficiency);

- Number of cage sets per row: 49 ÷ 2 ≈ 24.5 sets, with 25 sets per row (total 49 sets, 25 sets in one row and 24 sets in the other, and the error can be compensated by adjusting channels);

- Floor area per cage set: 2.88m (length of 4-tier cage) × 2.15m = 6.192㎡;

- Total length of single row: 25 sets × 2.88m = 72m (24 sets in a row is 69.12m, and the longest 72m is taken to unify the chicken house length).

2. Calculation of Chicken House Dimensions

(1) Width Design

| Area | Dimension (m) | Description |

|---|---|---|

| Total width of double-row cages | 2.15×2=4.3 | Each row is 2.15m wide, arranged side by side |

| Middle main channel | 1.5 | Meeting the needs of feeding trucks and personnel operations |

| Side auxiliary channels | 0.8×2=1.6 | Space for equipment maintenance and ventilation equipment installation |

| Total width of chicken house | 4.3+1.5+1.6=7.4m | Net width including all functional areas |

(2) Length Design

| Area | Dimension (m) | Description |

|---|---|---|

| Total length of cage arrangement | 72 | Calculated by the longest single row of 25 sets |

| Front buffer zone (wet curtain) | 1.5 | Space for wet curtain installation and air pretreatment |

| Rear equipment zone (fan) | 1.0 | Space for fan installation and maintenance |

| Total length of chicken house | 72+1.5+1.0=74.5m | Net length including functional extension areas |

(3) Height Design

| Area | Dimension (m) | Description |

|---|---|---|

| Total height of cages (4-tier) | 3.2 | Including the height of the cage frame |

| Height from cage bottom to ground | 0.8 | Reserved space for automatic manure conveyor belt |

| Height from cage top to roof | 1.5 | Space for ventilation airflow circulation and equipment installation |

| Eave height of chicken house | 3.2+0.8=4.0m | Height from ground to cage top |

| Ridge height of chicken house | 5.0m | Roof slope of 15° to improve ventilation efficiency |

3. Auxiliary Area Planning

An auxiliary functional area of approximately 25㎡ is set at one end of the chicken house (non-fan/wet curtain side), including:

- Feed storage area (10㎡): Storing 1-2 days of feed, close to the feed inlet of the feeding system;

- Equipment control room (8㎡): Placing automatic control systems, distribution boxes, etc.;

- Tool disinfection area (7㎡): Personnel entry-exit disinfection and tool storage.

III. Automatic Equipment Matching Scheme

1. Core System Configuration

| System Type | Configuration Details |

|---|---|

| Automatic feeding system | Adopt spiral feed lines, arranged above the double-row cages. The feed box capacity matches the daily feed intake of 49 cage sets (calculated as 120g per chicken per day, total capacity = 10,000×120g = 1.2 tons), with 2 feed boxes for zoned feeding. |

| Automatic drinking system | Nipple drinkers, 4-5 nipples installed per cell. Main water pipes are arranged along the side of the cages, equipped with filters and dosing devices to ensure water quality cleanliness. |

| Automatic manure removal system | Conveyor belt manure removal under the cages, 2 conveyor belts corresponding to the double-row cages, with the end connected to a manure collection box. Manure removal frequency is set to once a day (reducing ammonia accumulation). |

| Environmental control system | ① Ventilation: 4 negative pressure fans with 1.4m diameter installed at the rear (total air volume 4×30000m³/h, meeting the 20 times/h ventilation demand); wet curtains installed at the front (area 7.4m×1.5m=11.1㎡) for cooling in summer. ② Temperature control: Equipped with temperature sensors (accuracy ±1℃) and heating equipment (standby oil-fired hot air blower, activated at low temperatures) to automatically regulate the indoor temperature (20-28℃). ③ Lighting: LED light strips arranged along the channels, with light duration automatically adjusted according to the broiler growth stage (24h in the early stage, gradually reduced to 16h in the later stage). |

2. Equipment Linkage Logic

Full system linkage is realized through the central control cabinet:

- When the temperature is >28℃, fans and wet curtains are automatically activated; when the temperature is <20℃, wet curtains are turned off and heating equipment is activated;

- When the feed quantity is lower than the set value, an automatic alarm is triggered to prompt feed replenishment;

- Manure removal time is fixed at early morning daily (reducing stress on broilers).

IV. Chicken House Structure and Infrastructure Requirements

1. Main Structure

- Adopt light steel structure frame, with wind resistance grade ≥8 and seismic grade ≥7;

- Roof: Double-layer color steel plates (with 50mm insulation cotton in the middle), slope 15°, preventing rain and snow leakage;

- Walls: Side walls are color steel plates + insulation layers with strong sealing; front and rear walls reserve installation ports for fans and wet curtains.

2. Ground and Epidemic Prevention

- Ground: Cement hardening (thickness ≥10cm), inclined towards the manure outlet (slope 1%), facilitating flushing and drainage;

- Epidemic prevention: Disinfection pool (2m×1m×0.2m) and ultraviolet disinfection room are set at the entrance of the chicken house; in-house disinfection with chickens once a week, and thorough cleaning and disinfection during the empty house period (caustic soda + formalin fumigation).

3. Water and Electricity Supporting Facilities

- Power supply: 380V industrial electricity is required, with a total power of approximately 50kW (including fans, feed lines, heating equipment, etc.), and a standby generator (to prevent stress caused by power outages);

- Water supply: Connected to municipal tap water or deep well pumps, with water pressure ≥0.3MPa, and a water storage tank (capacity 5 tons) to ensure supply during water outages.

V. Summary of Scheme Advantages

- Efficient space utilization: Adopting 4-tier cages + double-row layout, the total area of the chicken house is only 74.5m×7.4m≈551㎡, and the land utilization rate is about 25% higher than that of 3-tier cages;

- Full automation: The whole process of feeding, drinking, manure removal, and temperature control runs automatically, requiring only 1-2 people to manage a single house, reducing labor costs;

- Controllable environment: Closed house + precise temperature control and ventilation reduce the invasion of external pathogens, and the survival rate of broilers can be increased to over 95%;

- Long-term durability: Cages adopt Q235 steel + hot-dip galvanizing process, combined with light steel structure chicken house, with an overall service life of ≥20 years, meeting ISO9001/SGS certification standards.

For further optimization (such as adding monitoring systems or adjusting the number of cage sets), the scheme details can be adjusted according to actual site conditions or breeding habits.