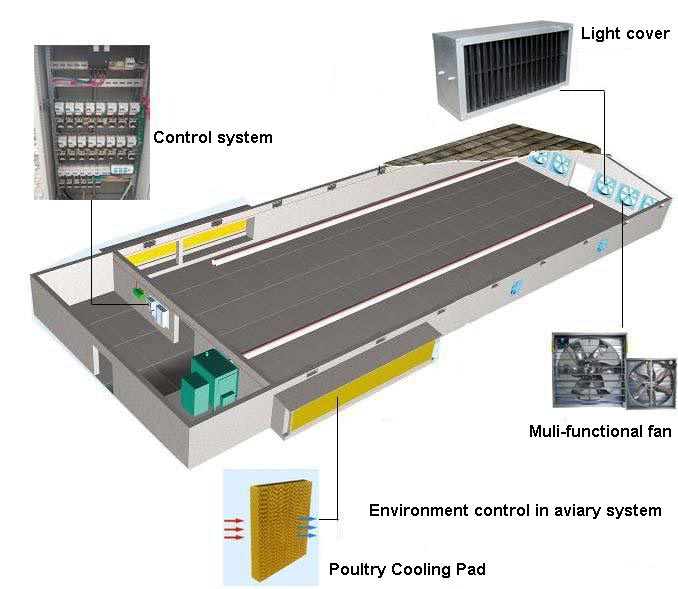

In the aspect of environment control in the aviary system for laying hens, precision control has already been achieved abroad. Environmental issues can be categorized into three types: one is light environment control technology; another is temperature environment control technology; and the third is air quality control technology, such as dust control. Traditional poultry farming environment control technologies mainly include the regulation of the light environment, air environment, and water environment. In a broader sense, environmental factors include welfare environments such as feeding methods, spatial environments like aviary systems for laying hens, and group environments such as stocking density.

Environment Management in Aviary System for Laying Hens

Light Environment Control

The light environment generally adopts energy-saving lamp modes. Recently, LED light sources have also been increasingly used. Many farms are adopting new energy-saving methods, not only in terms of light sources but also more importantly in the regulation of lighting duration. Now, new light sources are also being researched in terms of different colors of light. The later stages of lighting commonly use a 16-hour lighting schedule. Recent studies have shown that intermittent lighting may be more effective than using a 16-hour lighting schedule. For example, experiments on Beijing Fatty Chicken have shown that the intermittent lighting group performed better in several key aspects such as egg production rate and feed conversion ratio. Intermittent lighting saves a few hours and turns out to be more effective, allowing the chickens to rest in between, which actually aids in feed digestion.

The egg-laying time of Beijing Fatty Chicken is mainly concentrated between 8:00 and 14:00. The lighting time has a certain impact on the egg-laying time. As the lighting time is delayed, the egg-laying time also correspondingly delays, but turning on the lights early in the morning does not advance the egg-laying time. The shorter the lighting time, the more concentrated the egg-laying time.

Air Environment Control in Aviary System for Laying Hens

Temperature control is still a significant issue. In the past, the poultry industry focused more on cooling in the summer and keeping warm in the winter. However, spring and autumn are actually more problematic. The following discussion will focus on China as an example.

Because China has a continental monsoon climate on the Eurasian plate, the most critical time for disease prevention is during the spring and autumn when infectious diseases are more prevalent. This has a lot to do with large temperature fluctuations. Abroad, the poultry houses are now built to ensure that the temperature fluctuation within aviary systems does not exceed 2°C, which prevents high-yield breeds from getting sick because the environmental conditions can be guaranteed.

In China, the temperature fluctuations in poultry houses are generally very large. The design of poultry house buildings is lagging, and the concentrations of harmful gases and dust are very high. Even in the summer, when the southern regions are relatively humid, most places now use evaporative cooling pads. In the northern regions, north of the Yellow River, when the temperature rises to 28°C in summer, all the fans are turned on, and when it exceeds 30°C, the water pumps are turned on for cooling. When the water pumps are turned on, the temperature inside the house can be lowered by 6°C to 7°C through the cooling pads. However, under such temperature fluctuations, many farms find that chickens near the cooling pads are prone to colds. So, how should the temperature in aviary systems for poultry be regulated? The current general approach is to use intermittent regulation, turning the water pumps on and off intermittently, rather than waiting for the cooling pads to be fully wet before turning on the water pumps.

Ventilation Equipment and Its Efficiency in Aviary System for Laying Hens

As for the ventilation system, large agricultural fans are now commonly used on poultry farms. Abroad, fans used in livestock and poultry houses generally have a shroud or cap on the outside. We use an international standard large fan ventilation equipment performance testing system to measure, and its ventilation efficiency is increased by at least 15%. This means that at least 15% fewer fans need to be installed in each house, which offers certain benefits in terms of energy savings.

Designing a Reasonable Ventilation System

For ventilation systems, it is now recommended to use a model that allows air to flow directly from the sidewalls to the ceiling. Some international practices involve using fiber-compressed boards with strong air permeability, which allows cool air to be evenly distributed when passing through these boards. Combining this with ducted air delivery through the middle of the cages is an excellent approach.

In terms of air discharge, there is international consideration of using biological filtration methods for purification, especially in winter when ventilation rates are lower and dust concentrations inside the house are higher. By using biological agents to filter the discharged gases and dust, the filtered and purified air is almost odorless, which has proven to be quite effective. We also encourage the effective disinfection and filtration of discharged air, as this is highly beneficial for continuously maintaining the environmental quality of the farm area.

Air Environment Purification and High-Efficiency Disinfection Technology Development

Most farms are using in-house spray disinfection methods from the perspective of dust control and biosecurity. Disinfectant development is generally based on bacterial pathology, targeting specific bacteria with corresponding usage methods. After a period of time, bacteria may develop resistance, so alternating different disinfectants is a complicated process.

Now, a new type of slightly acidic electrolyzed water high-efficiency disinfection technology and equipment has been developed. Tap water is used as the main raw material, with diluted hydrochloric acid used for electrolysis. The equipment is low-cost in manufacturing and operation, and has high production efficiency. The new type of slightly acidic electrolyzed water is highly effective, broad-spectrum, and has stable sterilization effects. The active chlorine in the disinfectant produced by micro-electrolysis almost entirely exists as hypochlorous acid molecules, which have about 80 times the sterilizing power of sodium hypochlorite. It is safe and convenient to use, environmentally friendly, and does not require any adjustments after electrolysis—ready for direct use. The disinfectant is stable, and after sterilization, it reverts to ordinary water, leaving no residue or pollution, making it a green and environmentally friendly disinfectant.