Basic knowledge of commercial poultry incubator

Modern artificial incubation refers to a commercial poultry incubator that is automatically controlled by electric touch, accurately simulating the temperature and humidity of natural incubation, automatic timed egg turning, timed ventilation, fully automatic incubation, large one-time incubation volume, extremely low labor intensity, and high hatching rate. At present, the domestic and foreign hatching industries basically use commercial poultry incubators for incubation.

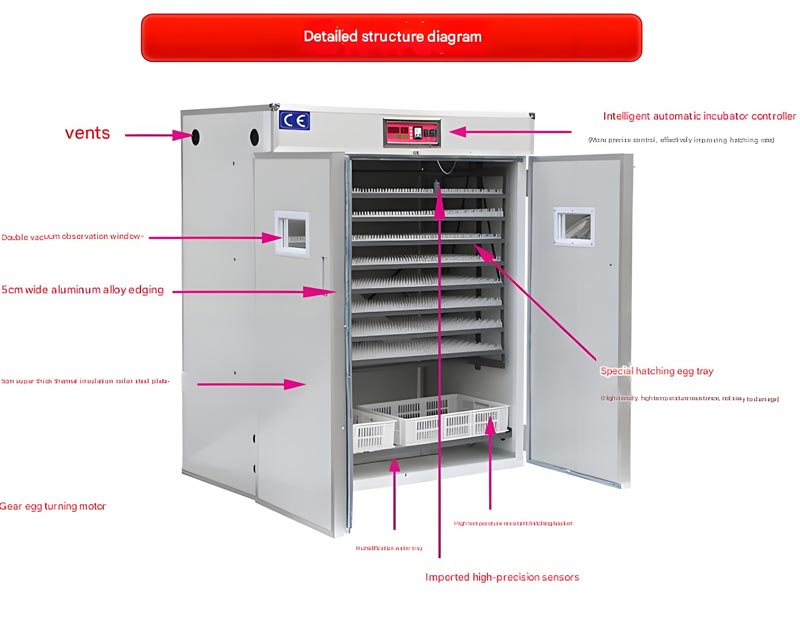

Controller

The heart of the commercial poultry incubator. The automatic heating, automatic acceleration, timed egg turning, timed ventilation, and automatic alarm functions of the entire commercial poultry incubator are completed by the controller.

Temperature

The optimal incubation temperature is 37~39.5℃, and the hatching temperature is 0.5℃ lower than the incubation temperature. The outlet setting temperature of the commercial poultry incubator is about 36℃, and it can be adjusted. The hatching is at the bottom and the temperature is suitable.

Humidity

The best humidity for incubation is 50~65RW, and the outlet of the commercial poultry incubator is set to 60 RW, which can be adjusted.

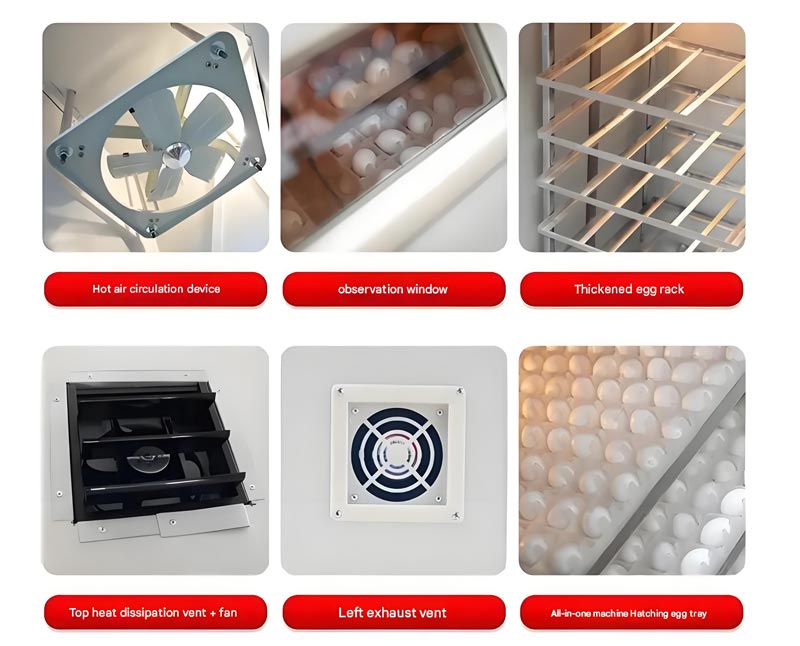

Ventilation

The embryo needs to inhale oxygen and expel carbon dioxide. The timed ventilation system can ensure fresh air in the normal commercial poultry incubator.

Turning eggs

Frequent egg turning can ensure that the embryo is heated evenly, prevent it from adhering to the shell membrane, and also help the embryo to move, which is conducive to the normal development of the embryo. The commercial poultry incubator is set to turn the eggs once every 2 hours, which is the best time and can be adjusted.

Alarm

When the environment or incubation is abnormal, the temperature deviation is 1℃, and the humidity deviation is 10%, the controller will automatically alarm and prompt the hatcher to take corresponding measures.

Egg candling: Lay the egg tray in incubation flat, use a special egg candling device to candling the eggs, and observe the development of the embryo.

Egg tray

A special tray for holding breeding eggs in the commercial poultry incubator. There are egg trays of different sizes according to different breeding eggs, such as chicken egg trays, duck egg trays, goose egg trays, multi-purpose egg trays, etc.

Wing board

A multi-layer plate egg rack that can be flipped up and down to place egg trays. Models below 5280 use wing board type for incubation.

Egg trolley

a cart-type egg rack. Models above 5280 use egg trolleys for incubation and hatching.

How should ventilation be controlled during artificial incubation of eggs?

In the early stage of incubation, eggs need very little oxygen. Generally, it is required to keep enough oxygen in the incubator or often, and the content cannot be less than 20%. The content of carbon dioxide cannot exceed 1%.

Carbon trioxide affects the safe growth rate of the embryo, weakens the body, and reduces the hatching rate. The insulation and ventilation of the incubator are a contradiction.

On the one hand, the insulation performance of the incubator should be good, and on the other hand, there should be a good ventilation device, increase the area of the inlet and outlet holes, set reasonably, properly layout, and add a good automatic reader, which can solve this contradiction and make the incubation get good results.

When using other incubation methods other than electric motors, such as flat box incubation, greenhouse incubation, coal incubation, etc., the eggs are often directly exposed to the indoor air, so special attention should be paid to the ventilation of the incubator to maintain fresh air and sufficient oxygen in the incubator.

Temperature control of incubator

The role of temperature

Temperature is one of the most important conditions in incubation, and plays a decisive role in hatching rate and chick rate. Because various metabolic activities in the process of embryonic development are carried out under certain temperature conditions, without a suitable temperature, the embryo cannot develop normally or develop abnormally, and a good incubation effect cannot be obtained.

In the early stage of incubation, the embryo’s material metabolism is in the primary stage and lacks the ability to self-regulate temperature, so a high-temperature starter is needed; in the middle stage of incubation, the embryo’s material metabolism is increasing day by day, and the body temperature regulation ability is gradually strengthened. At this time, the temperature remains stable, and the embryo has the ability to regulate body temperature. In addition, its own metabolism is vigorous and produces a lot of heat. At this time, it is appropriate to reduce the temperature moderately to facilitate heat dissipation. Therefore, the incubation process should follow the principle of high in the front, flat in the middle, and low in the back.

What to do if there is a temporary power outage during the incubator?

According to the specific conditions such as the power outage season, the length of the power outage, whether it is a regular power outage or an occasional power outage, and the embryos in the eggs in the incubator, take corresponding measures.

In early spring, the temperature is low, there is no heating equipment indoors, and the room temperature is relatively low (5-10℃). At this time, the inlet and outlet vents of the incubator are generally all closed. If the power outage lasts within 4 hours, no measures need to be taken. If the power outage lasts for a long time, heating equipment should be added indoors to quickly raise the room temperature to 25℃. If some embryos and eggs are about to hatch, but the number is small, the treatment method is the same as above. If there are many eggs in the hatching box, pay attention to prevent the center and the top layers of embryos and eggs from overheating. If you find that the eggs are too hot, you can adjust the plate.

If the temperature is over 25℃ and the egg embryos in the electric incubator are less than 10 days old, no measures need to be taken during the power outage. If the embryos are over 13 days old, the door should be opened first to lower the temperature in the machine. After the temperature of the top layers of eggs drops by 2-3℃ (depending on the size of the embryo), the door should be closed. Check the temperature of the top layers of eggs every 2 hours to keep them from overheating. If the door is opened in the hatching box, the cooling time should be extended. Wait until it drops by more than 3℃ before closing the door. Check the temperature of the top layers of eggs every hour. If there is a tendency to overheat, adjust the plate, paying special attention to prevent the eggs in the center from overheating.

When the temperature exceeds 30℃ and the power is cut off, if the eggs in the incubator are early eggs, no measures can be taken. If the eggs are mid- or late-stage eggs, the door must be opened (the air inlet and outlet holes have been spread out before), and the temperature in the incubator should be lowered to below 35℃. Then the door should be closed as appropriate (mid-stage eggs) or the door should not be closed tightly, leaving a gap (late-stage eggs). Check the temperature of the eggs in the top layers every hour. If the power outage lasts for a long time, or if the power outage is not long, but there is a regular power outage almost every day (such as 2 to 3 hours), the incubator should be adjusted once a day or every two days, as appropriate. In order to compensate for the low temperature caused by daily power outages (especially in areas with frequent power outages), the usual incubation temperature should be about 0.28℃ higher than the normal temperature standard. In this way, despite short-term power outages every day, the chick embryos can be guaranteed to hatch on the 21st day.

The role of turning eggs in commercial poultry incubator

When hens are incubating eggs, we can often hear the sound of eggs hitting each other. People have studied this phenomenon and found that turning eggs can prevent the embryo from adhering to the shell membrane, promote the movement of the amniotic membrane, and make all parts of the embryo evenly heated, which is beneficial to the development of the embryo. During artificial incubation, eggs are generally turned once an hour. The angle of turning eggs is preferably 45 degrees from the horizontal position to the left or right or front and back (depending on the model of the incubator). At present, most hatcheries use electric incubators with a high degree of automation. As long as the machine does not malfunction, the incubator will automatically turn the eggs once every certain period of time. But this does not mean that we can take it lightly. We should pay attention to observation and solve the problems of the machine not turning eggs, turning eggs at an insufficient angle, and vibrating too much at any time. For a long time in the past, people believed that eggs must be turned before 18 days of age. Recently, experiments have shown that stopping turning eggs no earlier than 16 days of age has no obvious effect on the hatching effect. This is very useful for some hatcheries with tight commercial poultry incubators. When necessary, the tray can be dropped in advance to speed up the turnover of the incubator.