Let’s look at a case with low egg production rate first:

A poultry farm with 35,000 laying hens (380 days old) reported an average egg production rate of only 84%, significantly below the expected 90%+. The farm owner suspected issues with feed or disinfectants, but after an on-site inspection, the real culprit was identified: poor environmental control.

Key Findings: Temperature Imbalance

The horizontal temperature difference (front-to-back) was 1.2°C, which seemed acceptable.

However, the diagonal temperature difference (from evaporative cooling pads to exhaust fans) was 8°C, creating hot/cold zones.

Egg production analysis by zone revealed:

- 26,000 hens (main area): 92% production

- 2,000 hens (corners, high-humidity zones): Only 72% production

Conclusion: Localized microclimate issues (high humidity, poor airflow) were dragging down overall performance.

Problems with egg production rates tend to overemphasize nutrition, but otherwise, climate control also plays an important role.

The key to a good automatic poultry in poultry farm

Fans

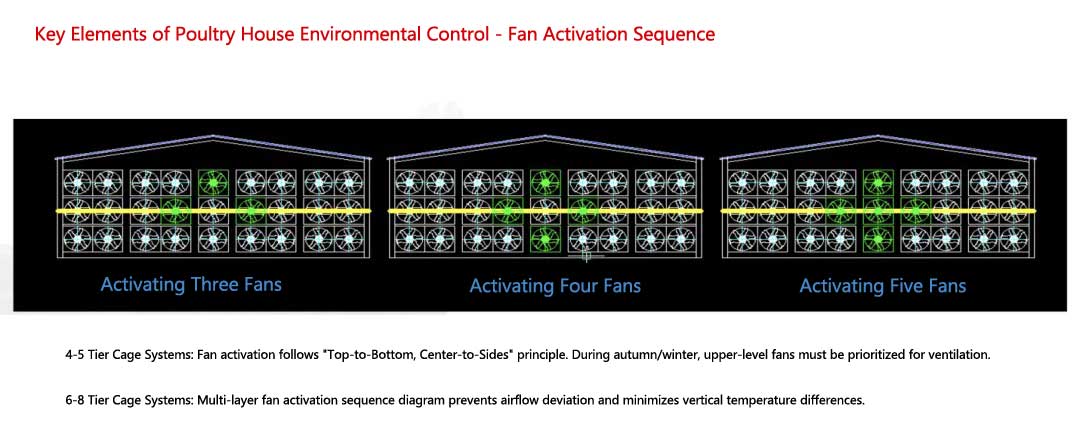

(1) Starting position of the fan

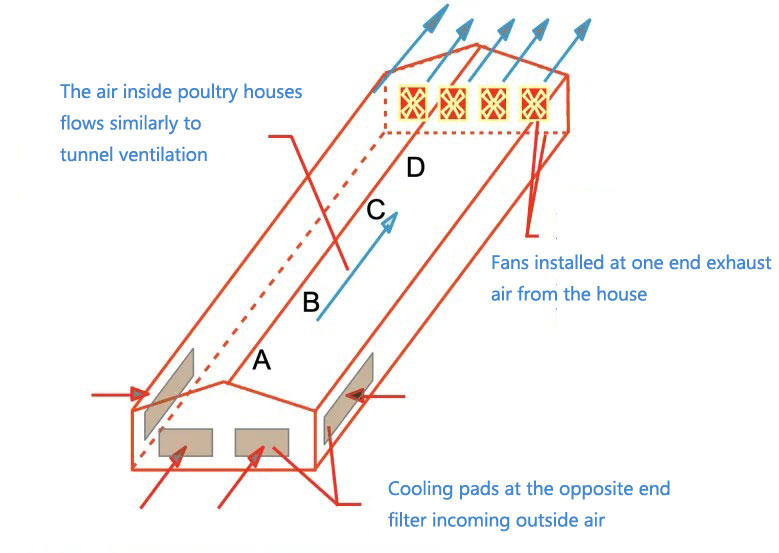

The essence of climate control is to control the flow of gases in the chicken house, through the airflow to move moist air, dust, and control the temperature, so as to get a result: a suitable environment for the chicken house.

Therefore, it is important to focus on the rear 1/3 (tail end) of the chicken house, in the area of 18-30 meters from the fan. This is also traditionally referred to as the weak wind zone, the formation of which is closely related to the location of fan start-up.

(2) Fan settings

In fact, the fan efficiency to refer to the effective air displacement, that is, the upper negative pressure of the air displacement. And fan nameplate exhaust air volume labeled on all static pressure air volume, using this data will be a problem. Therefore, the actual production of the design of the environmental control should be based on the farm configuration of the fan brand and age, and then go to find the fan negative pressure attenuation data, 20Pa negative pressure, 30Pa negative pressure in the case of the air volume, which calculates the chicken cage ventilation set the basic data.

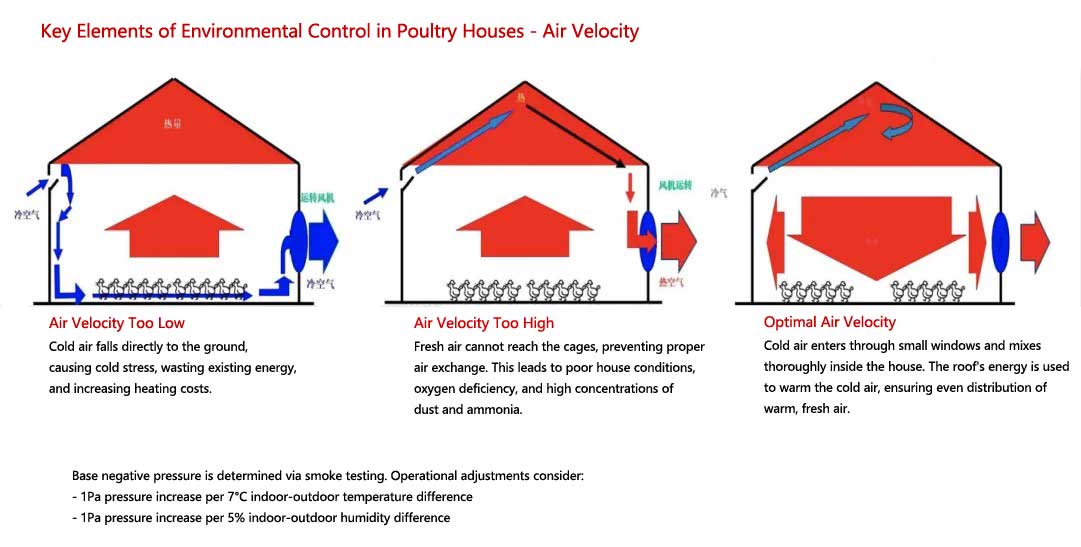

(3) Wind speed setting

Wind speed design generally first locked in the first advection wind speed, will be the state of the chicken coop without cages, the north 3.5 m – 3.6 m / s, the south 3.6-3.8 m / s.

After the chicken cage is built, the measurement of wind speed is based on the central aisle, which is required to be not less than 4.2 m/sec. In summer, when the fan is fully activated, the wind speed of the side aisle is required to be not less than 2.8 meters/second. If you can not reach, the whole chicken cage ring control cooling will be a problem.

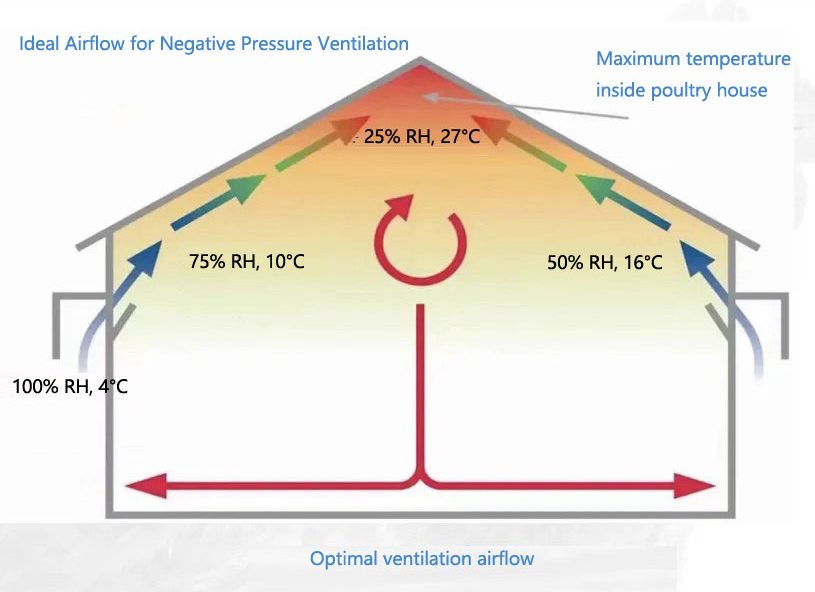

Because negative pressure is a feedback of wind speed, it is a key point of concern as temperature and other factors change. After accurate physical calculations, we conclude that the temperature difference between inside and outside the house increases by 7 degrees, the pressure should increase by 1 Pa; the humidity inside and outside the house increases by 5%, the pressure should be increased by 1 Pa. (Now, there are some incorrect statements in the field of prevention and control that the temperature difference increases by 3 to 5 degrees, increasing the pressure by 1 Pa, which is not based on the facts.)

This is why in the fall and winter seasonal change, in the 4, 5 layers of chicken cages in the cage house pressure level of 15 to 18Pa, 6, 8 layer is 10 to 12Pa pressure, cooling down when locking 25 to 30Pa pressure.

With the increase in humidity, to increase the wind speed of the air inlet, pull the wind pressure.

(4) Assistant fan

Assist in opening up the air, dust in winter, summer to prevent localized high temperatures and high humidity.

The role of the help fan is to ensure that fresh air into the chicken coop, used to solve the problem of poor air quality in the back 1/3 section of the chicken coop.

We found that the wind speed in the back 1/3 section of the chicken coop near the roof is low (6-8 meters/second), and the wind speed in the lower layer is only 3.8-4 meters/second, which causes air congestion. The booster fan assists the upper air flow speed to increase to 14 to 15 meters/second, so that the dirty air in the lower layer will be diluted upward, breaking the wind wall of the lower wind blockage, and the wind speed in the lower layer will be smoother, and the dust will be discharged with it.

In addition, the wind drives the heat, so that the heat to redistribute the area, the temperature difference between the front and back of the chicken cage will be smaller, basically 4, 5 layers in fall and winter, 100 meters of the chicken coop, the temperature difference between the front and back of the chicken cage can be compressed to 0.3 ~ 0.5 degrees. In summer there is the benefit of reducing the humidity in the rear 1/3 part of the house.

Key Design Parameters for Poultry House Environmental Control

| Item | Reference Standard | Parameter Values |

|---|---|---|

| Air Velocity | Heat exchange frequency | 3.5-3.6 m/s (Northern regions); 3.6-3.8 m/s (Southern regions) |

| Temperature difference <6°C | 25-30 seconds | |

| Fans | Effective airflow at 20Pa negative pressure | 42,000 m³/h (Static pressure); 33,000-36,000 m³/h (Negative pressure) |

| 5-10% additional fan capacity reserved | ||

| 1 fan per 5㎡ cooling pad | Installation height: 30cm ≤ H ≤ 40cm from ground | |

| Cooling Pads | 15≤Negative pressure≤20 | 2-2.2 m/s (Wetted); 2.4-2.5 m/s (Dry) |

| Size: 60*30cm | Stacked cages: 20-30cm from cage top; Spacing: 1.2-1.5m | |

| Inlet Windows | Meet 30%-35% of fan operation requirement | Stepped cages: 50-80cm from cage top; Spacing: 2.5-3.0m |

Cooling pads

Cooling pads for poultry houses settings to lock the water curtain air intake speed. At present, it is common to use an ordinary flatbed fan, matching 5 square meters of water curtain. The high wind pressure fan has to be reset according to the air volume.

The cooling pads for poultry houses’s air intake speed was first introduced from Germany, 1.8-2 meters per second after water injection. Because the cooling pads for poultry houses has 0.3-0.5 meters attenuation to the wind speed after water injection, therefore, in the real design of the pad wind speed, it should be calculated in accordance with the non-injection of water 2.4-2.5 m/s to ensure that there is still a wind speed of about 2 m/s after water injection.

If the setting is 2 meters / second wind speed, once the water injection of the actual wind speed is only 1.6 ~ 1.8 meters / second. In this case, you can only pull up the negative pressure of the chicken cage to increase the wind speed in the coop, but in the process of pulling up the negative pressure, the cage in the cage will form a cut on the airflow, resulting in an extremely uneven distribution of indoor temperature.

The position of the small window is different according to different floor design, the position of the small window is set according to the direction of the wind fall, the effect should be to achieve an effective exhaust dust and stop the cold air falling to the chicken living area.

The cooling pads for poultry houses have a direct relationship with the humidity in the summer house:

The application of cooling pads for poultry houses in summer is very critical, especially in the southern region, because it is itself high temperature and high humidity, and if the water curtain is not used properly, it will further increase the indoor humidity. High humidity is very important for eggshells, especially for dark.