Basic Broiler Chicken Cage Design Parameters

Based on the provided specifications of the A-type broiler cage, this design takes the 3-tier chicken cage as the core breeding unit, with the following key parameters:

Single cage size: 1830mm (length) × 2300mm (width) × 1500mm (height)

Cell specification: 610mm × 500mm × 370mm, each cell can hold 6 broilers weighing 2.5kg

Number of cells per cage: 3 (1830mm ÷ 610mm = 3)

Capacity per cage: 18 chickens (3 cells × 6 chickens/cell)

Equipment configuration: automatic drinking, automatic feeding, automatic manure removal, and automatic climate control

Calculation of the Number of Chicken Cages

To meet the breeding demand of 5000 broilers, the number of chicken cages required is calculated as follows:

Theoretically required number of cages: 5000 chickens ÷ 18 chickens/cage ≈ 277.78 cages

Actual configured number of cages: 278 cages (rounded up with a small amount of redundancy reserved)

Total capacity: 278 cages × 18 chickens/cage = 5004 chickens, which can meet the breeding needs

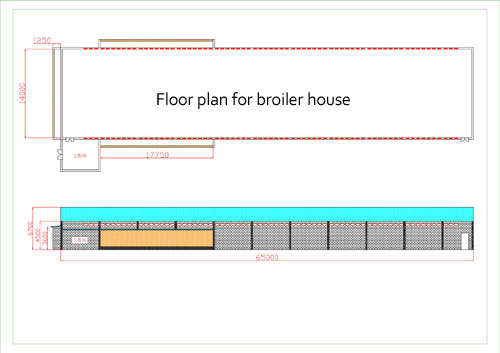

Design of the Main Dimensions of the Chicken House

Length Design

Adopting a double-row parallel arrangement, each row is equipped with 139 cages (278 cages ÷ 2 rows = 139 cages):

Length of a single cage: 1.83m

Total length of cages per row: 139 cages × 1.83m/cage ≈ 254.37m

Total length of the chicken house: 255m (including 0.63m reserved space for equipment at both ends)

Width Design

According to the layout of double-row cages plus the main passage:

Width of a single cage: 2.3m

Total width of double-row cages: 2 × 2.3m = 4.6m

Width of the main passage: 1.8m (to meet the passage of automatic equipment and personnel operation)

Total width of the chicken house: 4.6m + 1.8m = 6.4m

Height Design

Considering the height of the cage and the space for equipment on the top:

Height of the cage: 1.5m

Space for top equipment (ventilation, lighting, and environmental control equipment): 1.7m

Total height of the chicken house: 3.2m

Layout Planning of the Chicken House

Internal Layout

Breeding area: Adopting a double-row longitudinal arrangement, the two rows of cages are set in parallel, with the main passage in the middle. A 1.5m operation space is reserved between the ends of the cages and the ends of the chicken house.

Passage system: The main passage with a width of 1.8m runs through the entire length of the chicken house, used for the passage of automatic feeding carts, manure cleaning equipment, and daily inspection; the distance between the cage body and the side wall is 0.5m, serving as an auxiliary maintenance passage.

Equipment area: The following are set at both ends of the chicken house:

Feeding area: Equipped with a silo connected to the automatic feeding system, and the silo capacity is designed according to the feed consumption for 3 days.

Manure cleaning area: The end of the automatic manure cleaning belt is connected to a manure temporary storage pool, and the capacity of the pool is designed according to the manure amount for 7 days of cleaning.

Control area: Equipped with environmental control cabinets, power distribution boxes, and other equipment.

Ventilation and Lighting Design

Adopting a semi-open structure combined with automatic environmental control:

Side wall design: 30% of the lower part of the side walls on both sides are openable shutters, and 70% of the upper part is a fixed wall. The shutters are opened in summer to achieve natural ventilation, and closed in winter to enhance heat preservation.

Forced ventilation: One negative pressure fan with a diameter of 1.2m is installed every 30m along the length of the chicken house, and a wet curtain cooling system is set at the corresponding other end to form a longitudinal ventilation cycle.

Lighting system: One 200W LED waterproof lamp is installed on the top every 5m, combined with natural light from the side walls, to achieve adjustable light intensity (3 – 20lux).

Equipment Configuration Scheme

Core Breeding Equipment

Feeding system: Each row of cages is equipped with 3 feed troughs (25.0kg/3 lines), connected to the silo at the end, and 定时 feeding is realized through an automatic conveying device.

Drinking system: Each row of cages is equipped with 3 drinking lines (6.0kg/3 lines), equipped with nipple drinkers, connected to the filtered and disinfected water source to achieve automatic water replenishment.

Manure cleaning system: A scraper-type automatic manure cleaning belt is installed under the cage body, which runs regularly twice a day to transport the manure to the temporary storage pool at the end.

Environmental control system: Equipped with temperature and humidity sensors and CO₂ sensors, which automatically link with fans, wet curtains, and heating equipment (spare in winter) to maintain the temperature in the house at 18 – 28℃ and humidity at 50 – 70%.

Auxiliary Equipment

Disinfection equipment: An atomizing disinfection channel is set at the entrance, and a mobile disinfection cart is configured in the chicken house.

Monitoring system: High-definition cameras are installed to realize visual monitoring of the entire breeding process.

Emergency equipment: Equipped with a backup generator (to ensure the operation of equipment during power outages), fire extinguishers, and other safety facilities.

Structure and Material Selection

Main Structure

Frame: Q235 steel structure columns and beams are adopted, with a column spacing of 5m to ensure structural stability.

Wall: The lower 1.2m of the wall is a brick wall, the upper part is a color steel plate + insulation cotton composite wall, and the side wall shutters adopt a galvanized steel frame.

Roof: A gable roof with a slope of 15° is adopted. The roof material is color steel plate + 10cm thick insulation layer, and a ventilation cap is set at the ridge.

Ground Treatment

Ground in the breeding area: C25 concrete is used for pouring, sloping towards the manure cleaning direction with a slope of 2% to facilitate drainage and manure cleaning.

Passage ground: Anti-slip treatment is done, and a wear-resistant cement embossed ground is paved.

Chicken Cage Materials

Configured according to the parameters provided by the user:

Frame: Q235 steel

Mesh: Hot-dip galvanized steel wire mesh (service life of 20 years)

Feed trough and drinking line: Galvanized sheet, corrosion-resistant and easy to clean

Planning of Auxiliary Facilities

Disinfection room: A 10㎡ disinfection room is set at the entrance of the chicken house, equipped with facilities for changing clothes, shoes, and hand disinfection.

Material storage area: A silo foundation is set outside the end of the chicken house, and 2 50-ton feed silos are installed to ensure feed supply.

Manure treatment area: A manure composting site with an area of 50㎡ is set 30m away from the chicken house, using closed fermentation treatment.

Water source and power supply: An independent water well and a water storage tank (with a capacity of 50m³) are provided, connected to a 380V industrial power supply, and a backup power interface is set.

Design Highlights

Efficient breeding: Through accurate calculation of the number and layout of cages, high-density scientific breeding of 5000 chickens is realized, with a space utilization rate of over 85%.

Automatic operation: The whole system is automatically controlled, reducing manual intervention and lowering the labor intensity of breeding.

Environmental friendliness: Automatic manure cleaning and manure fermentation treatment are adopted to reduce environmental pollution; the semi-open design combined with forced ventilation ensures air quality in the house.

Strong durability: The core equipment is made of hot-dip galvanized materials, with a service life of 20 years, reducing long-term maintenance costs.