Quality grading of eggs worldwide

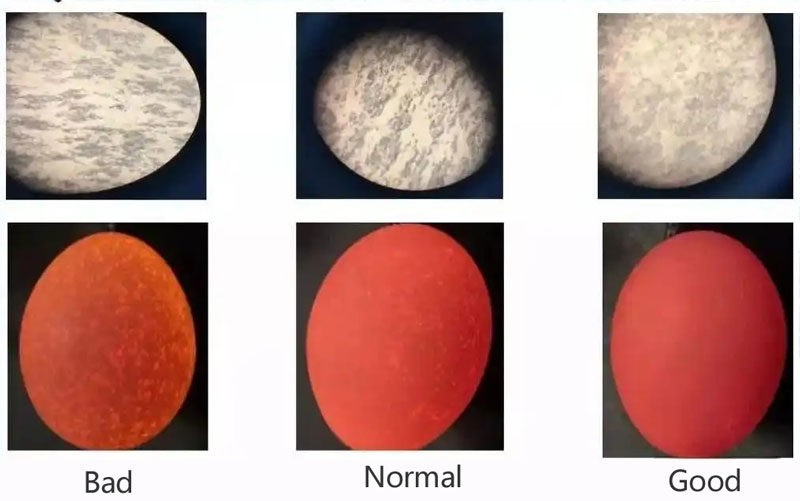

According to the United States standards, Grades, and Weight Classes for Shell Eggs 2000 and UNECESTANDARD EGG-1 EGGS-IN-SHELL, the quality of fresh eggs is classified into AA, A, and B.

Foreign standards are divided into AA, A, and B levels. The standard for AA grade eggs is extremely strict, requiring the eggshell to be clean and flawless, the egg shape to be neat and undamaged, the height of the air chamber to be strictly controlled below 3.2mm, and the protein to be clear and firm in texture. The yolk should be tight and have a clear and visible contour, presenting a high circular state with almost no defects.

The standards for A-level eggs are slightly relaxed, and the eggshell also needs to be kept clean. The egg shape should be normal and undamaged, the height of the air chamber should not exceed 4.7mm, the protein should be clear and firm, the yolk should be tight, the contour should be clear and visible, and it should also present a high circular state with almost no defects.

The standard for B-grade eggs is more relaxed, with slight dirt allowed on the eggshell, irregular egg shape but no damage, air chamber height exceeding 4.7mm, watery protein ground, clear and visible yolk contour, flat and slightly enlarged shape, and small blood spots and flesh spots allowed.

External quality of the egg

Eggshell quality

Good eggshell quality is important for ensuring food safety and minimizing economic losses. The quality of eggshell depends on its structure, which can be subdivided into four levels of structural analysis: apparent structure (visible to the naked eye), microstructure (under the light microscope), ultrastructure (under the electron microscope), and crystal structure (X-ray crystal diffraction).

The apparent structure of the eggshell is visible to the naked eye, which directly reflects the overall quality and appearance characteristics of the eggshell. By observing the apparent structure of the eggshell, it is possible to make a preliminary judgment on the freshness of the egg, the presence of cracks or breakage, and the presence of other potential food safety problems. Therefore, it is important to understand the apparent structure of eggshells to ensure food safety.

Eggshell Strength and Thickness

Eggshell strength, i.e. the maximum stress that the eggshell can withstand, is an important indicator for assessing egg quality. According to international standards, an egg should be able to remain intact under a pressure of 2.94×10⁵ Pa (equivalent to 30 atmospheres) when placed vertically, and the rate of egg breakage should be no more than 1% in the pressure range of 2.65 to 3.5×10⁵ Pa. It is important to note that eggshell strength can be affected by breed, rearing environment and nutritional status, with white-shelled eggs tending to have a higher breakage rate.

In addition, the longitudinal axis of the egg is more resistant to stress than the horizontal axis, therefore, it is recommended to arrange the eggs in a vertical manner during transportation and storage. Eggshell strength can be measured by means of a specialized eggshell tester and the results are given in kg/cm² or pa.

Eggshell thickness is a key factor affecting the compressive strength of the eggshell, and is also an important indicator of the quality and economic value of the egg. Normally, eggshell thickness should be 0.35mm or above to ensure good compression resistance for long distance transportation and storage. It is worth noting that eggshell thickness has a significant effect on the breakage rate.

Egg shape index and eggshell color

Egg shape index, i.e. the ratio of the longitudinal axis to the transverse axis of an egg, or expressed as the ratio of the transverse diameter to the longitudinal diameter of an egg, is presented as a percentage. Normal eggs are oval in shape and have an Egg Conformation Index (EMI) in the range of 1.3 to 1.35, i.e., between 72% and 76%. If the Egg Shape Index deviates from this range, the egg is considered substandard.

The color of the eggshell is a combination of the pigments contained in the eggshell and the membrane on the shell. Eggshell color is closely related to the strength of the eggshell. Usually, the higher the pigment content, the thicker the eggshell, and the corresponding increase in its compressive strength. Eggs with darker shell color tend to have a higher economic value in the market.

Other Characteristics of Eggs

The specific gravity of an egg is a key indicator of its freshness, and at the same time, it can also indirectly reflect the thickness of the eggshell. Through the salt water floating method, we can determine the specific gravity of an egg, i.e. the buoyancy of an egg in a sodium chloride solution.

Egg cleanliness is one of the important indicators to assess the quality of eggs. The cleanliness of the egg mainly depends on the presence of stains on the eggshell and the size of the area of the stains. Stains on the eggshell not only affect the appearance quality of the egg, but also have a significant impact on the consumer’s willingness to buy.

Broken and cracked eggs are not uncommon in eggs, with their percentage often exceeding 6%. Eggshells serve as a critical barrier to protect the contents of the egg and are essential to the preservation and packaging of the egg.

Other substandard eggs include rainy, sweaty, frozen, rotten, moldy, and hatching eggs, all of which can adversely affect the quality and profitability of eggs.

Automatic egg sorting machine — ensuring you get great quality eggs

Precision grading technology for egg sorting machines

The modern egg processing industry realizes millisecond weight detection, 0.1mm crack identification and freshness sorting through high-precision weighing, intelligent image recognition and near-infrared spectroscopy technology. The automated solution of handling 60,000 eggs per hour helps enterprises to increase packaging efficiency by 40% and reduce costs by 30%.

In the modern egg processing industry, accurate grading is the core link to improve product quality and optimize production efficiency. By integrating advanced technology, the egg grading and processing equipment realizes multi-dimensional accurate grading in terms of weight, appearance and internal quality, providing an efficient and reliable solution for the industry.

Weight sorting technology

The equipment adopts high-precision weighing sensors, combined with intelligent algorithms, which can detect the weight of eggs at millisecond level. Taking a certain model grading machine as an example, its sorting accuracy reaches ±1 gram, and it can classify eggs into XXL, XL, L, M, S and other grades to meet different market demands. For example, eggs exported to the European Union need to meet specific weight standards, egg sorting machine for sale can ensure that each egg accurately matches the requirements of the target market.

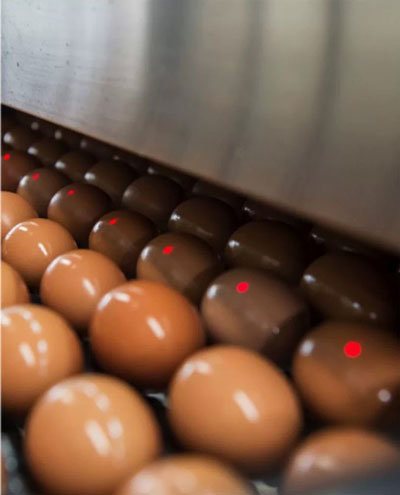

Appearance inspection technology

Through LED light inspection and image recognition technology, egg sorting machine can automatically identify cracks, stains, deformities and other defects in the eggshell. Multiple groups of LED light sources illuminate the eggs from different angles, and with the high-speed camera capturing images, the system uses deep learning algorithms to analyze eggshell characteristics and reject substandard products. For example, the system can detect tiny cracks with a width of only 0.1 millimeters to ensure the quality of egg appearance.

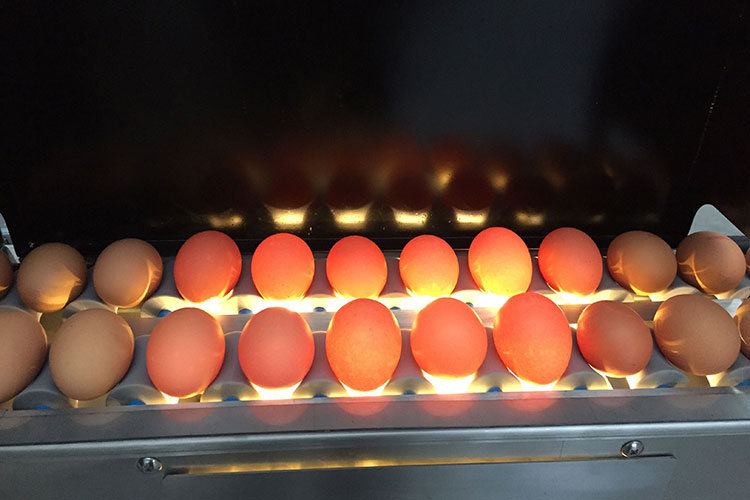

Internal quality sorting technology

Some high-end equipment introduces near-infrared spectroscopy or acoustic detection technology to assess internal indicators such as yolk concentration and air chamber size. For example, by analyzing the light transmittance of eggs, the HAF unit (freshness indicator) can be indirectly judged, and internal quality grading such as AA grade and A grade can be realized.

Automated packaging and data management

The sorted eggs can be automatically loaded into egg trays of different specifications and spray printed with production information. The equipment is equipped with color touch screen and PLC control system, which can count the number of eggs at all levels in real time and support remote parameter adjustment and fault diagnosis. For example, an enterprise has improved packaging efficiency by 40% and reduced labor cost by 30% through this system.

Technical advantages of our egg sorting machine for sale

(1) Manual hand-held/automatic egg sucker can suck 30 eggs to the egg conveyor at one time.

(2) Egg conveyor has LED light inspection (with light inspection cover) and six rows to single row function.

(3) Egg washing machine host, including disinfection spray, brush cleaning, air drying and oil spraying functions.

(4) Egg grading machine (hanging and grabbing grading machine), including six rows of egg collection and transportation, ultraviolet ray sterilization, automatic turnaround, grading and counting functions.

(5) Egg packaging machine (3 groups), each group contains 1 feeding device and 1 egg conveyor belt, manually put the empty egg trays into the feeding device, the feeding device automatically transports the empty egg trays to the place where the eggs fall down, and the egg trays filled with eggs are output through the belt, and then manually packed in boxes.