Slatted floor system in poultry

Slatted floor system in poultry mainly refers to the method of keeping chickens off the ground and raising them on meshes made of plastic. In order to facilitate management and the cleaning of chicken manure, there will be a certain distance between the slat floor and the ground.

Advantages of FamTECH’s slat Floor

1. Recyclable. After cleaning and crushing, some raw materials of the slatted floor can be molded again to create new floor which can still be used for about six years.

2. Easy to install, uninstall, clean and sanitize.

3. Improve poultry health and poultry productivity.

4. Sturdy non-porous polypropylene floor inhibits bacterial growth.

5. Reduce cleaning time and labor cost.

6. Suitable for any size poultry house. Panels can be easily cut and assembled.

7. Suitable for different animals. Flatness can be easily controlled with its four supports.

8. No burrs, protect the bird’s legs and feet from damage.

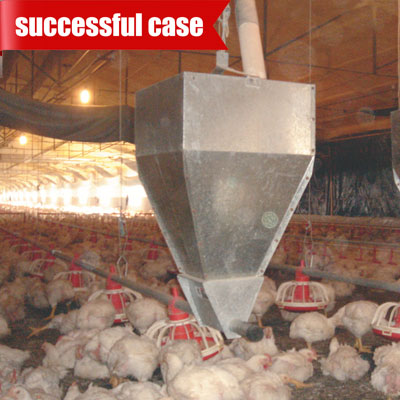

Successful case from FamTECH

Details of plastic slatted floor

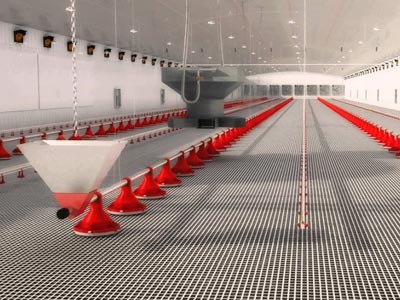

Chicken feed pan

SPECIFICATIONS

Material: 100% brand-new PP

Service life: 10-12 years

Weight: 676±g

Diameter: 330mm for pan of 14 grilles; 360mm for pan of 16 grilles

Separation distance: 3 pans/3 meters; 4 pans/ 3 meters

Feeding quantity: 40-50 birds/pan

AGVANTAGES

- V-shape chicken feed pan can effectively avoid wastage of feed;

- Superior virgin PVC material prolongs its life to 10+ years;

- The chicken feed pan is disassembly. After disassembled, the plate is suitable for baby chicken of 0-7 days old.

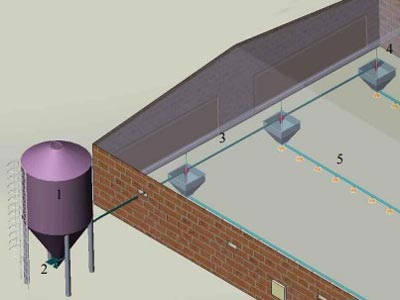

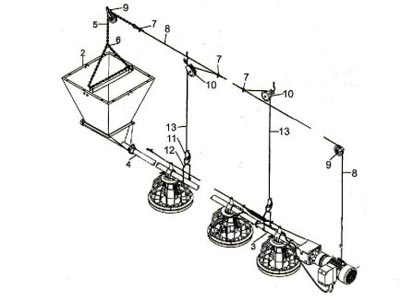

Automatic poultry feed line

SPECIFICATION

Motor: Taiwan brand, IP55 protection class, 0.75kw/1.1kw of power

Sensor: Germany imported/domestic, installed in the feed pan or the bottom of the hopper

Anger: 36mm of diameter, South Africa imported, high-carbon manganese steel

Delivery pipe: 3/4 holes per 3m, 45mm of diameter, 275g/㎡ galvanized sheet; 1.2mm of thickness

Feed Hopper

Material: hot galvanized sheet

Size: 600*600/800*800 mm

Thickness: 1.00 mm

Capacity: 120L

Advantages: 1. The funnel-shaped feed hopper makes sure the feed enters the feed delivery pipe smoothly;

2. The hot galvanized sheet material is anti-corrosion and durable

Poultry drinking system

SPECIFICATION

Nipple drinker: made of stainless ball and PVC shell, 12/15 drinkers per meter

Medicine doser: DOSATRON from France

Water Pipe: round(better quality)/square(easy cleaning); max length is 150m

Water Purifier: provides clean water for 50,000 birds

Drinking line: distance between 2 drinking lines is 2.5-3m

Water regulator: made of PVC

AGVANTAGES

- Effectively prevent the contact between water and chicken manure and avoid ammonia emission;

- Superior material of nipple drinker not only ensures smooth drinking of chicken but also guarantees a long service life;

- The health of chicken is ensured by imported medicine doser can water regulator which can also take the quickest response to the emergence of small or large scale disease.

Poultry ventilation system

SPECIFICATION

Blade: imported from Germany, made of galvanized sheet and equipped with 3C certified motor with IP54 protection class, can open automatically

Air inlet window: 600*320*160mm in size; can be open automatically or manually; made of high-quality plastic and stainless steel

Cooling pad: natural water absorption is 60~70mm/5min and 200mm/hour; the size is customizable

AGVANTAGES

- Ventilation system is an indispensable part of large-scale slatted floor system in poultry,

- The ventilation system can effectively clean the air and reduce the temperature in chicken house to maintain chicken’s health;

- The materials are non-toxic, harmless,green, safe, energy-saving, environmental protection, economical and applicable.

Advantages of slatted floor system in poultry

1. In line with international development trends. The European Union promulgated a ban on cages. And in 2027, caged animals will be completely banned in the EU. Under this circumstance, the slatted floor system in poultry has promising prospects and markets.

2. Chicken manure will fall under the slat floor so that chickens do not directly contact the manure, which is conducive to disease control.

3. The stocking density is high. Averagely, 1 square meter can accommodate 4.8 chickens.

4. The cost is lower than that of cage raising and the chicken manure can be recycled, which can improve the income and reduce the cost;

5. It can significantly reduce the incidence of coccidiosis, colibacillosis, chronic respiratory disease, fowl cholera and ascites, reduce drug costs, and improve the survival rate of chickens

6. Since most of the management work is done in the corridor, it can reduce stress and facilitate the management of the chicken house;

7. It is easy to control the temperature and humidity of the chicken house, facilitate ventilation, and improve the stocking density.

8. The chicken has a wider range of activities, and the egg-laying performance of the chicken is relatively good.

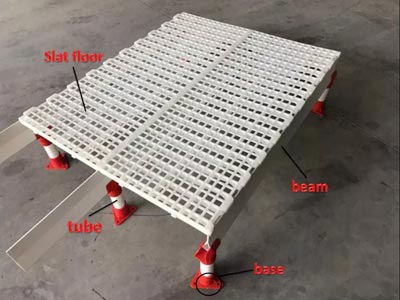

Slat Floor

Parameters of FamTECH’s slatted floor

| Slat foor | ||||

|

Type |

Unit |

Size/mm |

Mesh/mm |

Weight/kg |

|

1 |

pcs |

1200*500*40 |

16*16 (for baby chicken) |

2.0 |

|

2 |

pcs |

1200*500*40 |

20*20 |

2.0 |

|

3 |

pcs |

1200*500*40 |

20*24 |

2.3 |

|

4 |

pcs |

1200*500*40 |

18*40 |

1.65 |

|

Base |

Made of PVC, the height is adjustable from 280mm to 500mm |

|

Beam |

Height(material): 9cm(PVC)/12cm(PVC)/15cm(FRP); |

|

Length: 3/4 m | |

|

Tube |

Diameter: 5cm, made of PVC |

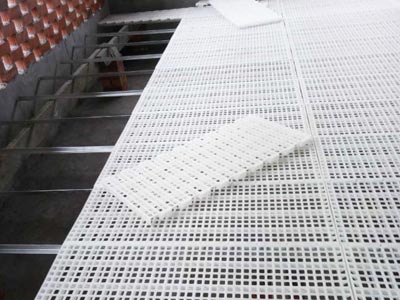

Successful cases of FamTECH’s poultry slatted floor

Benefits of slatted floor system in poultry

Improved Hygiene and Disease Control

One of the primary advantages of using a slatted floor system is its contribution to improved hygiene and disease control. The design of the slats allows droppings to pass through, preventing direct contact between the birds and their waste. This reduces the risk of bacterial and parasitic infections, resulting in healthier birds.

Better Manure Management

Slatted floors facilitate efficient manure management. The droppings that fall through the slats can be collected in a pit or a manure removal system. This makes it easier to remove and dispose of the waste, reducing the risk of bacterial contamination in the poultry house. Proper manure management also prevents ammonia build-up, creating a healthier environment for the birds.

Enhanced Air Quality

By allowing droppings to fall through the slats, the slatted floor system in poultry helps maintain better air quality within the poultry house. The reduced contact between the birds and their waste minimizes ammonia emissions, which can have detrimental effects on respiratory health. Improved air quality translates to healthier birds and improved overall productivity.

Reduced Footpad Lesions

Conventional flooring systems, such as solid concrete, can lead to footpad lesions in poultry due to prolonged exposure to wet litter. Slatted floors, on the other hand, allow droppings to pass through, keeping the surface drier and reducing the risk of footpad problems. This leads to better foot health and improved welfare for the birds.

Design considerations for slatted floor system in poultry

Slatted Floor Material

The choice of material for the slatted floor is crucial. It should be strong enough to support the weight of the birds and resistant to corrosion and degradation caused by the waste. Common materials include high-density polyethylene (HDPE), fiberglass-reinforced plastic (FRP), and galvanized steel.

Slit Size and Orientation

The size and orientation of the slits in the floor also play a role in its functionality. The gaps should be wide enough to allow waste to fall through but narrow enough to prevent the birds from getting stuck or injured. The orientation of the slits should facilitate easy cleaning and waste removal.

Load-Bearing Capacity

The slatted floor should have sufficient load-bearing capacity to support the weight of the birds without flexing or breaking. This ensures the longevity of the system and minimizes the risk of injury to the birds.

Slatted Floor Slope

To facilitate efficient waste removal and prevent pooling of liquids, the slatted floor should be installed with a slight slope. This allows gravity to assist in the movement of waste towards the collection area.

FAQs

Q1: Can the slatted floor system be used for all types of poultry?

Yes, the slatted floor system is suitable for various types of poultry, including broilers, layers, and breeders. However, specific design considerations may vary depending on the bird’s size, age, and breed.

Q2: How often should the slatted floor be cleaned?

Regular cleaning of the slatted floor is necessary to maintain hygiene and prevent waste buildup. The frequency of cleaning depends on factors such as flock size, ventilation, and waste management system. As a general guideline, daily or weekly cleaning is recommended.

Q3: Can the slatted floor system be used in free-range or organic poultry production?

Yes, the slatted floor system can be utilized in free-range or organic poultry production. However, it’s important to comply with the relevant regulations and standards to ensure the welfare and organic certification requirements are met.

Q4: Is it possible for birds to injure themselves on the slatted floor system?

Proper design and maintenance of the slatted floor system minimize the risk of bird injuries. Attention should be given to slit size, orientation, and material selection to prevent birds from getting stuck or experiencing footpad problems.

Q5: Where can I find more information on implementing a slatted floor system?

For more detailed guidance on implementing a slatted floor system in your poultry house, consult reputable poultry management resources, seek advice from experienced farmers, or reach out to agricultural extension services in your region.