Layer chicken cage is a more popular solution of breeding layer chickens wordwide, the reason why it is so popular is that the design of the chicken layer cage provides a comfortable environment for the chicken so that the chicken plays a better role in the feeding process, the main advantages of the design of the layer cage are manifested in the front net and cage door, the density of cage feeding, and the angle of rolling eggs.

FamTECH provides A-type and H-type layer chicken cages

A-type layer chicken cage

Full-Step Layer Chicken Cages

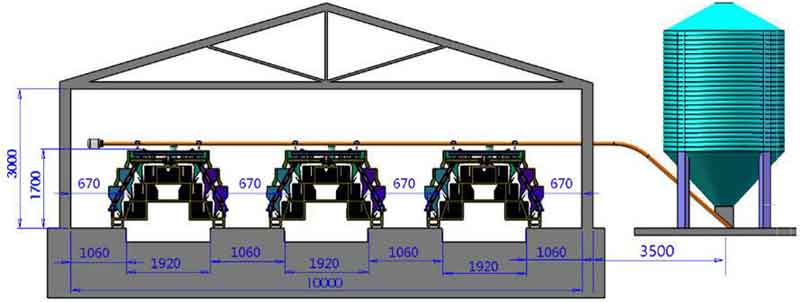

Full-step layer chicken cages utilize a multi-tiered (typically 2 to 4 levels) staggered arrangement, where each tier is offset vertically. This design enables direct manure drop into the central manure pit, reducing overall stocking density compared to stacked cages and improving flock management conditions.

Semi-Step Layer Chicken Cages

Semi-step layer chicken cages feature a partially overlapping structure between upper and lower tiers. The overlapping section incorporates a sloped manure retention plate to prevent fecal contamination of lower cages. Proper installation requires adjusting the plate’s tilt angle to facilitate efficient manure flow into the collection pit.

H-type layer chicken cage

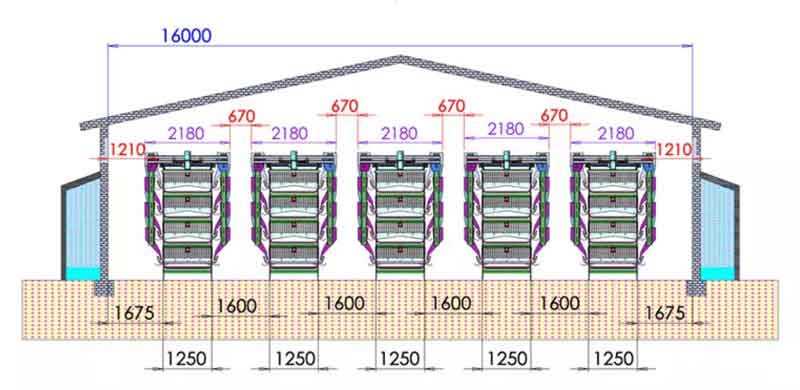

Multi-layer battery cage for layers is unique in its design, characterized by overlapping layers separated by a 12cm high spacing between the layers. This design is not only flexible and versatile, but can also be flexibly set from 3 to 12 layers of overlapping according to the different scale of farming. Even more advanced, each layer is equipped with a conveyor belt in the middle to receive and transport chicken manure. Through automation technology, the chicken coop realizes all-round control of manure removal, feeding, water supply, egg collection and environmental regulation. The application of this kind of layer cage significantly improves the utilization efficiency and productivity of the chicken house, and is now widely adopted in most large-scale egg laying chicken farms.

Advantages of battery cage for layers

The scientific chicken layer cage design will effectively reduce the fatigue of the chicken in the cage, improve the egg production rate, and reduce the egg damage rate.

The national standard Q235 steel endows layer chicken cage with good elasticity, so it has no deformation, and does not sag for life.

Double-layer galvanizing, so that the chicken layer cage can serve for years without rusting, the service life can reach 10-20 years.

The chicken feeding door can be changed arbitrarily, and more chickens can be accommodated to eat together.

The layer chicken cage design structure is simple and less material is used, so the cost is low.

The installation is relatively simple and easy to use.

Reduce the chance of chickens getting injured

It can better protect the feathers of the chicken.

Automatic poultry equipment for layer chicken cage

Automatic Drinking System

The drinking system includes water pipes, water tanks, pressure regulators, nipple drinkers, front-end water devices, and medication systems, which can be customized based on client requirements.

High-quality water pipes, pressure regulators, and nipple drinkers effectively prevent leaks. The closed-pipeline system minimizes water contamination.

360° nipple drinkers provide sufficient water supply for poultry at all growth stages.

Learn more

Automatic Feeding System

The automatic feeder is an economical and practical machine featuring simple operation, remote-controlled movement (travel speed: 9–12 m/min), and easy management.

Automated control with adjustable feed delivery.

Smooth operation, low noise, and long service life.

Arch-shaped structure with high load-bearing capacity and anti-deformation properties.

Learn more

Automatic Egg Collection System

Travel speed: 5–6 m/min. For an 80-meter chicken house, eggs can be collected within 20–30 minutes.

Advantages:

Improved efficiency: The conveyor system transports eggs from cage egg trays to the house’s front end or egg storage room, reducing labor and boosting productivity.

Reduced breakage: Equipped with anti-slip mechanisms, buffer devices, and abnormal egg screening, it minimizes egg damage and enhances market value.

Lower labor intensity: Eliminates manual egg collection, cutting costs for large-scale farms.

Higher egg quality: Reduced human handling decreases breakage rates, improving overall product quality.

Learn more

Automatic Manure Removal System

Conveyor belt system reduces labor intensity and costs while maintaining a dry, clean environment.

Ideal for large-scale farming.

High-quality PP (polypropylene) manure belts. (Cleaning speed: 2–4 m/min).

Learn more

Environmental Control System

Designed for intensive farming, customizable smart poultry farming systems are available.

Real-time monitoring: Tracks temperature, humidity, CO₂ levels, and ventilation to optimize airflow and climate conditions, ensuring ideal production environments for higher efficiency and egg yield.

Disease prevention: Predicts and mitigates health risks through early detection, safeguarding flock health and product quality.

Learn moreLayer cage price for 5000 hens(for reference)

Here’s a structured table summarizing the pricing and features of automated layer chicken cage systems for 5,000 laying hens:

Price Comparison of Automated Layer Chicken Cage Systems (5,000 Hens Capacity)

| Category | Price Range (USD) | Key Features | Suitable For |

| Medium Automation | 20,000–20,000–50,000 | Basic automation (feeding, drinking, manure removal) | Medium-sized farms |

| High Automation | 50,000–50,000–100,000+ | Advanced features (environmental control, egg collection, data monitoring) | Large-scale farms |

| Customized Systems | $100,000+ (varies) | Tailored solutions (high-capacity, precision environmental controls, etc.) | Specialized farm needs |

Factors Affecting Price

| Factor | Impact on Cost |

| Equipment Capacity | Larger systems (5,000+ hens) increase price. |

| Automation Level | More features (e.g., climate control, data tracking) = higher cost. |

| Material Quality | Stainless steel/galvanized steel cages cost more than standard materials. |

| Brand & Supplier | Reputable brands charge premium prices but offer better reliability/service. |

| Installation/Shipping | Additional fees may apply for setup and transportation. |

Materials for layer chicken cage

The key to choosing the material for chicken cages is to meet the needs of feeding planning. In the market, there are various choices of materials for chicken cages.

Cold galvanized (electro galvanized)

Cold galvanized, also known as electro galvanized, has a relatively thin zinc coating. Typically, this material begins to show signs of rust after 2-3 years, with an overall service life of about 6-7 years. However, its cost is relatively affordable, so it is suitable for large family farmers or short-term farmers. But from the perspective of long-term use, this material may not be the best choice.

Cold galvanized (electro galvanized)

Cold galvanized, also known as electro galvanized, has a relatively thin zinc coating. Typically, this material begins to show signs of rust after 2-3 years, with an overall service life of about 6-7 years. However, its cost is relatively affordable, so it is suitable for large family farmers or short-term farmers. But from the perspective of long-term use, this material may not be the best choice.

Electrostatic spraying

Electrostatic spraying, also known as electrostatic spraying, works by using powdered paint adsorbed on the cage under the action of high-voltage static electricity, which in turn forms a layer of highly corrosion-resistant phosphating film. Once the phosphating film is cured on the surface of the cage, its stability is extremely high, not easy to peel off, even in a strong acidic environment can remain intact, ensuring its durability, service life of up to 15 to 20 years.

Zinc-Aluminum-Magnesium alloy plate

Zinc-aluminum-magnesium alloy plate is in the traditional hot-dip galvanized layer based on the integration of aluminum (Al) and magnesium (Mg) elements, thus forming a high corrosion resistance and high cut edge protection performance of the coated steel plate. As verified by outdoor exposure experiments, its corrosion resistance has been significantly improved, and its service life has been extended by 3 to 5 years compared with ordinary galvanized sheets. In addition, the corrosion resistance of this alloy plate in the cut edge is also enhanced, containing magnesium elements of zinc-based corrosion products will naturally cover the surface of the cut edge, play a protective role, that is, the surface of the scratched surface can be self-repairing part of it, so as to slow down the speed of rusting.

When choosing chicken cages, you also need to pay attention to the manufacturer’s galvanizing process. Usually, first processed into the cage mesh and then hot-dip galvanized process, compared with the first galvanized process, can significantly extend the service life of the cage mesh, as much as 5 years or more. This is due to the fact that the process of processing and then galvanizing better protects the welded joints from corrosion.