What is broiler cage for sale

Broilers enter battery cage for broilers at the age of 5-7 weeks, and leave the pen when their weight reaches 2-4 kg (the specific time varies according to breeds and feeds). The broiler battery cage system usually adopts a three-dimensional structure of 3-5 layers (which can be customized), which can make full use of the vertical space and increase the density of breeding per unit area. It is made of galvanized iron wire or plastic, which is corrosion resistant and load bearing, and the bottom of the cage is designed as a mesh for manure to leak down. Adjusted according to the chickens’ growth stage, each cage generally holds 5-10 broilers.

FamTECH provides 3 solutions for broiler farming: A type, H type and automatic harvesting broiler cage.

A type broiler chicken cage size

|

Cell Capacity |

6 birds (2.5kg), 7 birds (2.0kg) |

|

Cell Size(mm) |

610*500*370 |

|

Cage Size(mm) |

1830*2300*1500(3 tiers) |

H type broiler chicken cage size

|

Cell Capacity |

9 birds (2kg), 10 birds (2.5kg) |

|

Cell Size(mm) |

650*625*430 |

|

Set Cage Size(mm) |

2230 (height of cage)*2150 (width)*2550 (total height) (3 tiers), 2880*2150*3200 (4 tiers) |

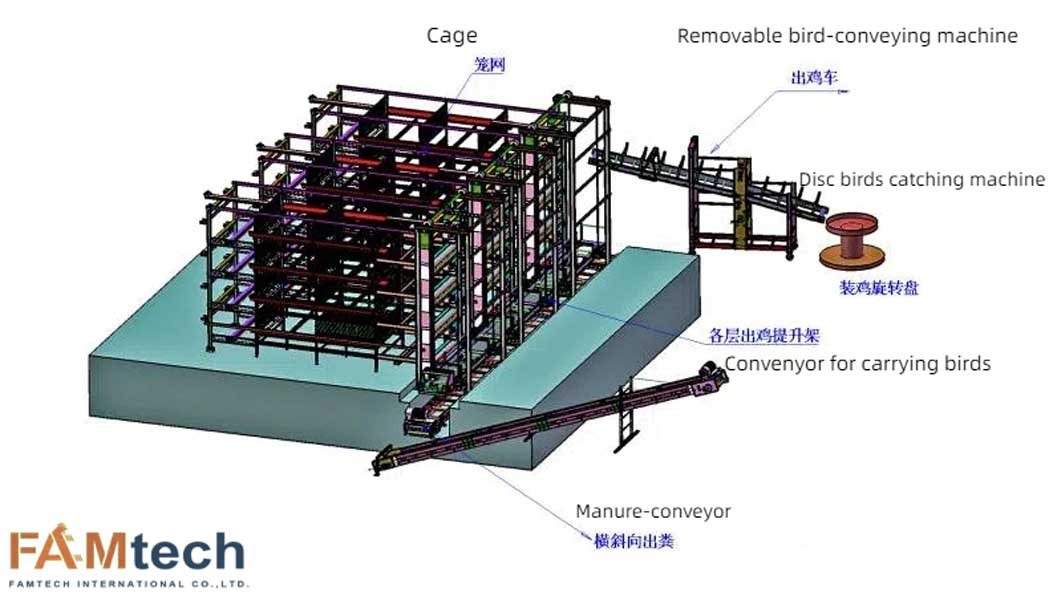

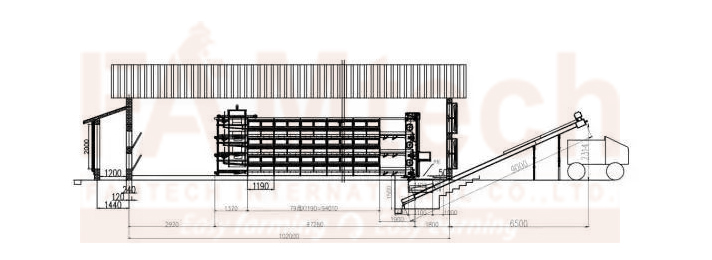

Automatic harvest broiler cage

The automatic harvest broiler cage is an automated equipment specially designed for broiler farms, mainly used to efficiently, quickly and with reduced stress remove chickens from the cage and convey them to transport trucks or slaughtering lines when they reach their pen weight. It is usually used in conjunction with A/H type battery cages for broilers, which significantly reduces the labor intensity of manually catching chickens, improves the efficiency of chicken release, and at the same time reduces the damage and stress of chickens.

Advantages of automatic harvest broiler cage

Automated chicken catching/catching: through conveyor belt, mechanical arm or guiding system, the chickens are smoothly moved out from the cage, avoiding the rough operation of manual catching.

Centralized conveying: Convey chickens to the outlet in a centralized manner for easy loading or docking to the slaughtering line.

Reduced stress: Gentle handling reduces panic in chickens, minimizing deaths or quality degradation (e.g. bruises, fractures).

Efficient discharge: Handles thousands of chickens per hour, 5-10 times faster than manual labor, suitable for large farms.

Structure of automatic harvest broiler cage for sale

System Components:

Movable cage floor panel (galvanized steel/plastic) with tilt/open function

Anti-slip conveyor belt (PVC/rubber, 30-60cm wide, 0.3-0.8m/s adjustable speed)

Collection/sorting platform with optional counting/weighing/robotic systems

Drive/control unit with variable-speed motor and PLC/microcontroller

Key Features:

Manual/electric/pneumatic operation options

Single-layer or multi-layer convergence designs

Automated functions available (counting, weighing, crating)

Safety mechanisms included, adaptable to different farm scales

Working principle of automatic harvest broiler cage

Workers or the automated system activate the mechanism, causing the floor panels to tilt gradually or open fully. Chickens slide onto the conveyor via gravity (some designs use gentle vibrations to assist).

The conveyor operates at low, steady speed to transport chickens from each tier to the collection platform. Multi-tier systems use convergence devices to merge chickens onto the main belt.

At the platform, workers or robotic arms load chickens into crates (10–20 birds per crate to avoid overcrowding). Advanced systems may include auto-weighing + counting, with data uploaded to farm management software.

Broiler cage design from FamTECH

The main frame is hot-dip galvanized sheet, the thickness of galvanized layer is 275g/㎡.

The cage wire as a whole is hot-dip galvanized after welding, with special galvanizing process, no zinc slag, long service life.

Transverse and longitudinal connection structure is strong and reliable, yet simple and efficient, to ensure the cage body is stable and no collapse.

Adopting large net door overall inward push type, more convenient for human operation.

With operation car track, convenient for observation, catching chickens and protecting the food trough.

The overall height of the cage can be adjusted with the height of the chicken house, which is convenient for breeders to observe the chickens and catch chickens.

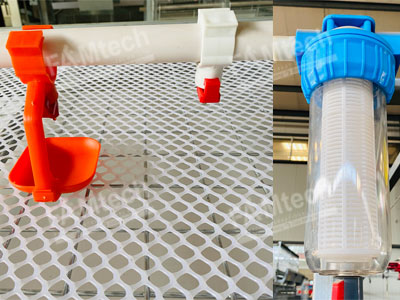

Longitudinal manure belt is made of PP belt with smooth surface, high strength, complete manure clearing and avoiding running away. Transverse manure cleaner is hot-dip galvanized as a whole, made of PVC, and installed in the whole ring to ensure the strength, usage effect and long life span.

Uniformly upgraded drinking water system with reliable quality to avoid leakage. Reduce labor and avoid water line damage caused by human error.

Why do you need a broiler battery cage system

Broiler battery cage system increases the breeding capacity by more than 3 times compared with the traditional breeding method, effectively saves the site, and at the same time improves the feeding density and increases the production.

Multi-layer farming ensures a hygienic and healthy growing environment for the chickens, which can effectively increase the body weight and feed conversion rate, and can increase one breeding batch per year;

At the end of each breeding batch, cleaning and disinfection can be carried out quickly and easily, reducing the time between batches.

Fully assembled, high precision installation and easy maintenance.

High-density rearing saves land, high space utilization, easy to realize intensive and large-scale rearing.

Automatic manure cleaning system reduces the chance of cross-infection of chickens and improves the survival rate, and also provides a clean and comfortable growing environment for chickens, which is conducive to their healthy growth.

It facilitates feeding management, greatly reduces the number of operators, lowers labor intensity and improves labor productivity.

Due to the reduced activity of chickens in the cage, energy consumption is reduced, thus reducing the waste of breeding feed and effectively saving the breeding cost.

Easy to assemble, can be adjusted according to the site, can be retrofitted with automatic watering, automatic feeding, automatic manure removal, to realize the breeding automation.

Special specifications, can come to sample customized, also can be customized according to requirements.

Why choose FamTECH

Premium Materials

Carefully selected high-quality materials with superior load-bearing capacity, smooth edges, and rational structure

Customization Support

Rigorous craftsmanship ensures wear-resistant and easy-to-clean surfaces

Ample Inventory

Direct factory supply with sufficient stock, prompt delivery, and comprehensive after-sales service

20+ Years Expertise

Cost-effective solutions with multiple international certifications for guaranteed quality