Profound market potential for aviary system product

In 2004, cage-free egg production in EU countries accounted for 25% of the total production. By 2014, this proportion had reached 50%, representing a 100% growth rate. Over the past decade, statistics on the sales of caged and cage-free eggs in the United States and Canada clearly show that in the past three years, sales of caged eggs have decreased by 40%, while sales of cage-free eggs have increased by nearly 50%. The United States plans to convert more than two-thirds of its egg industry to welfare farming by 2025.

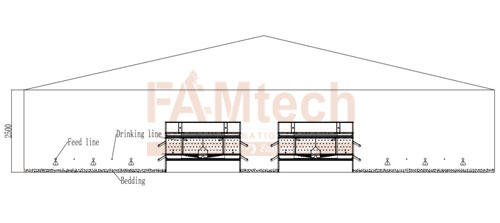

Application of aviary system

The appropriate age of chickens for an aviary system can vary depending on the design and setup of the system, as well as the specific goals of the poultry operation. However, aviary systems are generally used for laying hens, typically starting from pullets (young hens) around 16-18 weeks old when they are ready to be introduced to the laying environment.

FamTECH also provides other cage-free solution such as slatted floor system and cage system.

Specification of FamTECH’s aviary poultry systems

FamTECH provides two types of aviary poultry systems

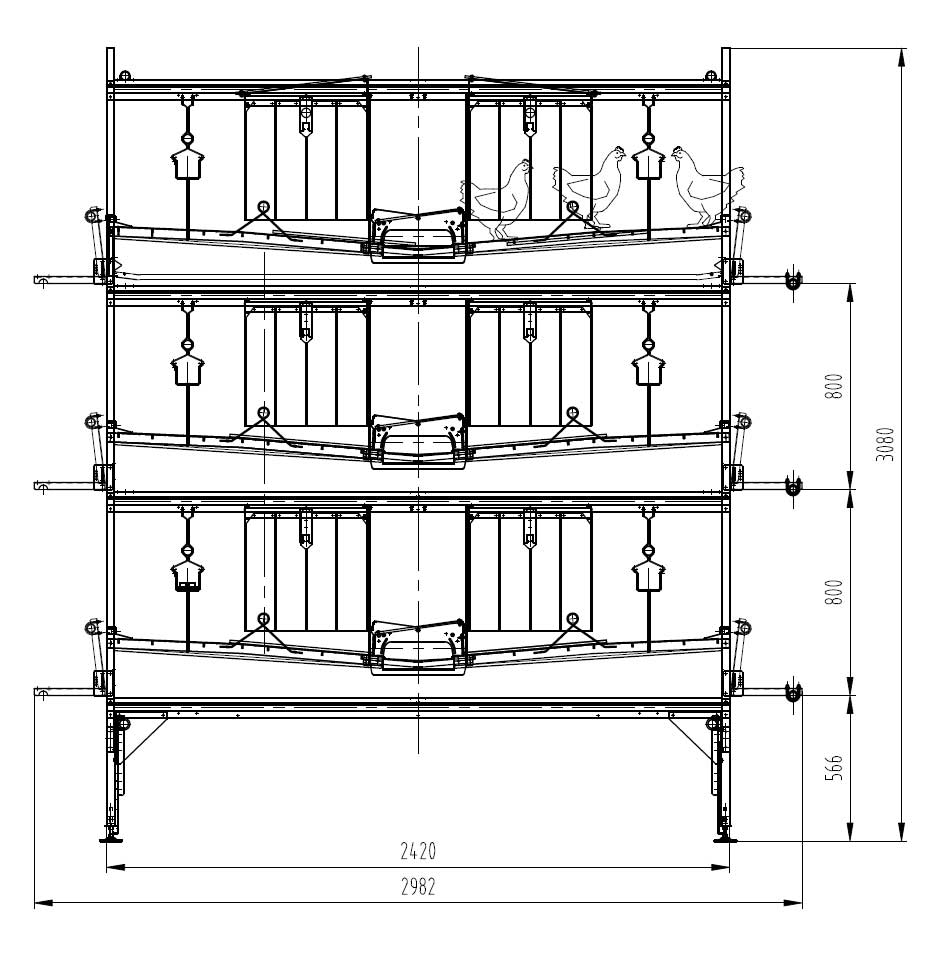

Specification of type A aviary system

| Size for each set | 2900*2982*800mm |

| Capacity per set | 100 chicken |

| Egg laying box per set | 2 |

| Egg laying box size | 1000*470mm |

Central Egg Collection Design: This design allows chickens to enter the nesting box from both sides, with the nesting boxes staggered on either side of the egg belt. This arrangement makes it easier for staff to observe the chickens and perform maintenance on the equipment.

Egg Nest on Each Layer: Each layer is equipped with an egg nest, chain feeder, and drinker.

Open Nesting Boxes: All sides have curtains, which increase the privacy of the egg nests while reducing product costs.

Non-continuous Egg Nests: Chickens can move freely between nests, fully utilizing the space above the conveyor belt.

Stainless Steel Base: The base is made of stainless steel.

Ladders on Cage: Ladders are provided to help chickens access each platform layer.

Specification of type B aviary system

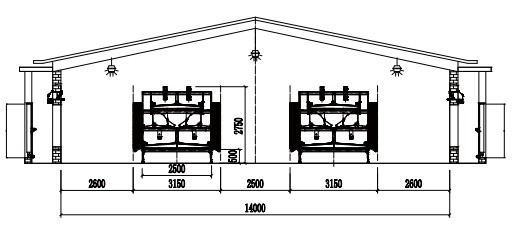

| Size for each set | 1150*3150*2750-2850mm |

| Capacity per set | 92-120 chicken |

| Egg laying box per set | 2 |

| Egg laying box size | 1150*500mm |

Advantages of FamTECH’s aviary system

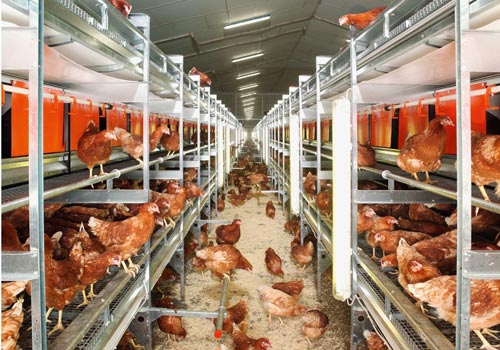

Free Activity Space

Unlike traditional cages, this aviary system provides a broad area for poultry to move freely, promoting muscle development, improving immunity and well-being, and reducing stress. Encourages chickens to engage in activities like perching, scratching, and stretching, leading to healthier and more active birds.

Smart Environmental Control

An advanced system integrates temperature and humidity sensors, ventilation, and lighting control, automatically adjusting to provide the optimal environment for the birds at different growth stages. This intelligent management makes farming easier and more efficient.

Efficient Feeding

The automated feeding system accurately controls the amount and timing of feed, reducing waste and increasing feed conversion rates. Customizable feed formulas meet the needs of different growth stages.

Easy Cleaning and Maintenance

An automatic manure cleaning system reduces the workload of manual cleaning, keeping the environment clean and sanitary. The equipment’s design facilitates regular inspection and maintenance.

Health Monitoring and Alerts

The system is equipped with intelligent health monitoring to track key indicators such as poultry behavior, weight, and egg production rate. It sends alerts if any abnormalities are detected, ensuring safe farming.

Eco-Friendly and Energy-Saving Design

The use of energy-efficient materials and technologies reduces energy consumption and carbon emissions. The optimized ventilation system minimizes the release of harmful gases like ammonia, protecting the environment.

Feeding Space

Activity Area: Provides ample space for laying hens, greater than that of caged systems. In multi-layer cage-free systems, each chicken has enough room to stand, walk, and spread its wings.

Resting Area

Designated resting areas for laying hens to rest and lay eggs. These areas are designed to be quiet and comfortable, encouraging hens to lay eggs.

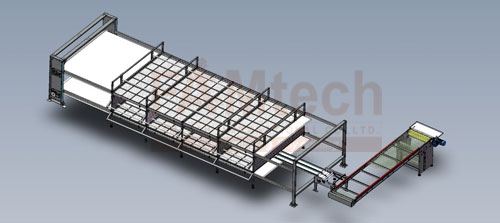

Fully automatic cage free aviary system

Automated Feeding System

Feed Management: Ensures the freshness and quality of feed, with regular cleaning to prevent mold and spoilage.

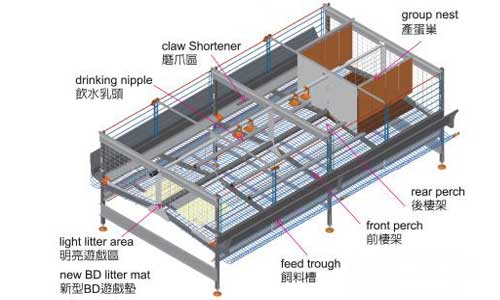

Trough Design: The troughs are spacious and flat, making it easy for hens to feed. Smooth edges prevent injury to the hens’ beaks.

Automated Feeding: Uses an automatic feeder to dispense feed into designated troughs according to a preset schedule, reducing labor costs and ensuring hens receive food on time. Automatic feeders reduce labor costs and ensure that the hens have access to food at all times.

Automatic Drinking System

Stable Water Supply: Ensures a stable supply of clean, sanitary drinking water, providing hens with adequate hydration.

Water Purification: Includes purification devices like filters and UV sterilizers to remove impurities and pathogens, ensuring water safety.

Drinker Choice: Common poultry drinkers include bowl drinkers and nipple drinkers, with nipple drinkers preferred in cage free aviary system for their water-saving and anti-pollution benefits.

Pipeline Layout: Uses corrosion-resistant, non-toxic materials like stainless steel or PVC for water pipes, ensuring adequate water flow to each drinking point.

Environmental Control

Temperature and Humidity: An intelligent temperature control system ensures that the temperature and humidity in the poultry house remain within the appropriate range, reducing disease and increasing productivity.

Lighting: The cage free aviary system provides suitable light intensity and duration to promote growth and egg production. The lighting system can be adjusted to meet the needs of different growth stages.

Ventilation: A well-designed ventilation system ensures fresh air in the poultry house, reducing the concentration of harmful gases like ammonia and hydrogen sulfide.

Egg Collection System

Egg Collection System:A well-designed egg collection system reduces the labor intensity and breakage rate of collecting eggs.

Nesting Boxes: Provides ample nesting boxes in the poultry house for hens to lay eggs. Designed to be spacious and comfortable, with soft bedding to reduce egg breakage.

Perch Setup: Provides ample perches for hens to rest and sleep, designed to be stable and safe, preventing injury.

Egg Collection: Uses an automatic or manual system to collect eggs from nesting boxes promptly. Automatic systems use conveyors to transport eggs to collection points, reducing labor and breakage.

Smart Management

IoT Technology: Utilizes IoT to monitor environmental parameters (such as temperature, humidity, light intensity, etc.) in real-time, automatically adjusting control equipment accordingly.

Data Analysis: Collects and analyzes data such as egg production, mortality, and feed consumption to provide scientific support for farm management.

Remote Monitoring: The remote monitoring system allows real-time viewing of the poultry house conditions, enabling timely problem-solving.

Hygiene Management: Regularly cleans nesting boxes and collection systems to maintain hygiene. Eggs are graded, packaged, and processed to ensure product quality.

Litter Management: In cage-free systems, litter serves as an important area for hens to rest and lay eggs. The litter is absorbent, pollution-free, and regularly changed to maintain dryness and cleanliness.

We provide free design service