Customizable service

20+ years manufacturing experience

High-quality material

Worry-free service

IOS9001 certified

Battery cage for broilers is used for large-scale broiler chicken raising. This broiler chicken cages for sale can be manual, semi-automatic and fully automatic based on customers’ needs. The structure is simple but stable, which is easy to operate and maintain. The relatively wide cell distance allows A type broiler cage to have good performance in open house, and provides enough light for chicken.

Besides A type broiler chicken cages for sale, we also provide H-type broiler cage.

FamTECH also provides all kind of automatic battery cages for rabbit, quail, duck, pigeon.

Product picture of FamTECH’s broiler chicken cages for sale

Why choose FamTECH

FamTECH is a professional company specializing in the production, research, development, and sales of livestock farming equipment. Over the past 20 years, we have accompanied numerous farmers through various challenges and changes. During this time, we have continuously updated our technological research and development, organizing technical staff to systematically study German technology to better serve both new and existing customers.

Our product range includes six series with over a hundred products, primarily categorized as

Cage system: fully automated standardized and custom-made cage systems for laying hens, broiler chickens, small chicken and breeding chicken.

Free poultry raising systems: such as aviary system, floor system. Large, medium, and small-sized watering processing and storage equipment for farming facilities.

Automated feeding systems: such as gantry-type, staircase-type, stacked-type, chain-driven-type, auger-type, and disc-type.

Temperature control equipment: including ventilation windows, fans, evaporative coolers, and water-heated heaters;

Manure cleaning: scraper-type, conveyor belt-type manure cleaning equipment and manure processing dryer and treatment equipment compliant with current environmental protection requirements.

Side-product handling machines include egg collection machines, egg grading machines, and egg incubators.

Our products cover a wide range of areas in poultry farming. In terms of company scale, product quality, and after-sales service, we are now among the leading domestic companies. We not only provide customers with high-quality products but also regularly organize training sessions on farming techniques and sales, and offer free on-site technical guidance.

Parameters of Broiler Cage for Sale

|

Service Life |

20 years of hot galvanized material and 12 years of cold galvanized material |

|

Certification |

ISO9001, SGS |

|

Material |

Q235 steel and cold/hot galvanized wire mesh and sheet |

|

Application |

open house or semi-open house |

|

Tiers |

3,4 (according to the height of house and your anticipate farming scale) |

|

Weight |

Chicken wire mesh-45.0kg, frame-14.0kg, feed trough-25.0kg/3 lines, water line-6.0kg/3 lines |

|

Automatic machines |

Automatic drinking, automatic feeding, automatic manure removing, and automatic climate control |

|

Age of birds | Day 1 to harvest day |

|

Cell Capacity |

6 birds (2.5kg), 7 birds (2.0kg) |

|

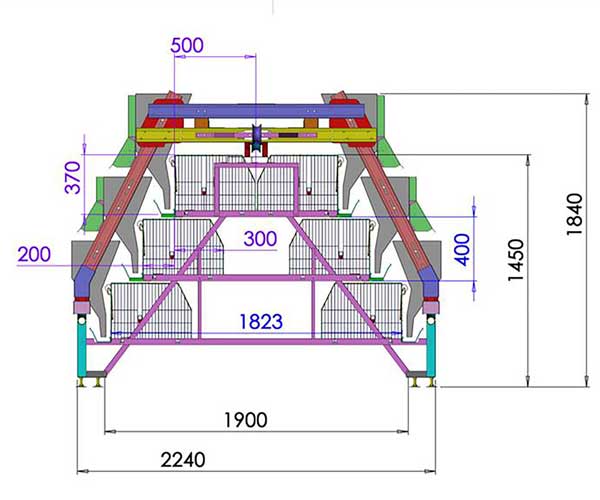

Cell Size(mm) |

610*500*370 |

|

Cage Size(mm) |

1830*2300*1500(3 tiers) |

Free broiler chicken cage design service & turn-key service

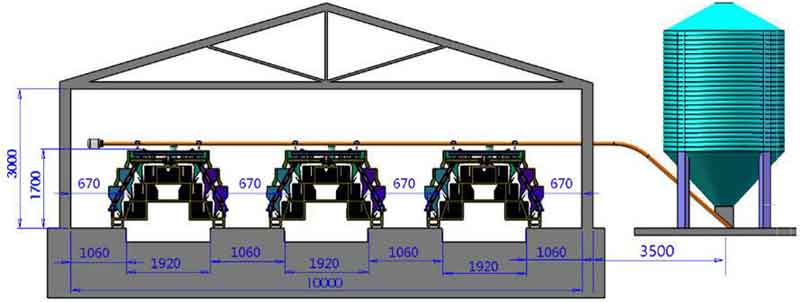

Here is a design scheme for semi-open broiler house with 5000 chickens. If you are interested, contact us to design your broiler chicken house.

Length Design

Adopting a double-row parallel arrangement, each row is equipped with 139 cages (278 cages ÷ 2 rows = 139 cages):

Length of a single cage: 1.83m

Total length of cages per row: 139 cages × 1.83m/cage ≈ 254.37m

Total length of the chicken house: 255m (including 0.63m reserved space for equipment at both ends) … Learn more details

Detailed introduction of FamTECH’s broiler cage system

Cage Material

International standard Q235 wire mesh of broiler cage is treated with 300-350g/m² cold or hot galvanized. The thickness of wire mesh is 3.5mm. It is easy to clean and durable.

The frame for the broiler chicken cage for sale is 2.0mm aluminum-zinc 185-350g/m² hot galvanized sheet. The frame is stable and anti-corrosive.

Drinking System

FamTECH broiler cage’s drinking system is consist of nipple drinker with 304 stainless steel food and ABS engineering plastic, 2.0mm thick PVC water pipe and adjustable water pressure regulator. They are all toxic-free, rust-free, easy to install.

Water pressure regulator has backflush function of the water flow speed of 35kg/min to clean the pipe and nipple drinker to ensure the water quality for broiler chicken.

Feeding System

Feed system of A type battery cage for broilers has 1.2mm thick hot Galvan hopper trolley with 0.75kw driving motor to run 8.67m/min.

The feed trough of broiler cages alternative: 100% new PVC or hot galvanized steel. Both of the materials are rust-proof and nontoxic.

According to the feeding density of poultry house, our customers can choose different feed silo capacities: 4/8/10/13/15/20/33 ton.

Manure System of Broiler Cage

1.2mm thick PP manure belt works with galvanized scraper to clean broiler chicken thoroughly. The running speed of 3 meters per minute.

Automatic manure removal machine keeps the environment of chicken house clean, enhances the utilization rate of chicken manure.

Climate Control System of Broiler Cage

Fan: high-quality ventilation fan is made of hot galvanized frame and 430BA stainless steel. The fan’s average power is 36,000m²/h, which can efficiently discharge harmful gas and keep a high-level air quality.

Cooling Pad: It uses 150mm/200mm thick superior paper material to filter the harmful substances in the air and reduce the temperature of broiler chicken house, the size is also customizable.

Air Inlet: high-class PP material is employed, this machine can be automatic or manual.

All the parts above can be controlled automatically by EC-1211 climate controller.

Advantages of FamTECH A Type Broiler Cage — battery system with best price

Cost-effective and high ROI

- Reduce the sick rate of broiler chicken

- save cost in many perspectives

- be operated in an easy and sanitary way

- improve economic returns

- High-quality product from reliable broiler cage supplier

- 20+years experience with the best price

Excellent ventilation

Due to the staggered arrangement between each layer, air can circulate freely between the chicken cages, effectively reducing the temperature and concentration of harmful gases inside the chicken house, providing sufficient oxygen for the broiler chickens, and reducing the incidence of respiratory diseases.

Automated farming

Optional features for cleaning manure and adding feed and water are also more convenient. Additionally, the stepped broiler cage structure is relatively stable, capable of withstanding the pressure generated during the broilers’ growth process, ensuring a safe and comfortable growth environment for the broilers.

Uniform sunshine

The stepped structure ensures that each layer of chicken cages receives adequate lighting, providing broiler chickens with sufficient sunshine duration and intensity, which is beneficial for their growth and development.

Increased stocking density

The stepped design creates a certain height difference between each layer of chicken cages, allowing for efficient use of vertical space and improving the space utilization rate of the chicken house.

Easy to observe and manage

Caretakers can conveniently monitor the growth, feeding, and health status of broiler chickens in each layer of cages, enabling timely identification of issues and implementation of appropriate measures.

FAQs about FAQs about broiler cage system

Which international standards does the structure comply with?

The Type A frame complies with EU animal welfare standards, with cage spacing of 2.5-3 cm to prevent pinching injuries. The 12° inclined cage bottom has been internationally certified for easy cleaning of feces, and the cage door is equipped with a finger-safe latch that complies with OIE standards.

What certifications does it have? Is the material environmentally friendly?

Certified under ISO 9001, EU CE, and US FDA standards. Hot-dip galvanized lead-free (99.9% purity) meets RoHS requirements; the chrome-plated layer has been tested by SGS and meets environmental standards in Japan, South Korea, Europe, and the Americas.

Which regions and climates are suitable?

Suitable for intensive farming in Southeast Asia, Europe, the Americas, and South America. Tropical models feature a 120μm zinc coating for corrosion resistance; cold regions can add insulation layers for stable use from -15°C to 40°C.

How is packaging ensured during transportation?

Export-grade fumigation-free wooden crates, secured with EPE pearl cotton, with rust-proofing for critical components. Wooden crates withstand 1500N pressure, single-unit packaging emphasizes center of gravity, with a spare parts kit included.

Transportation methods and lead times?

Sea freight (full container load/less than container load) or air freight available, supporting FOB/CIF/DDP terms. Overseas warehouses ship within 48 hours; domestic production: standard 15–20 days, custom 25–35 days, plus 15–45 days for sea freight to port.

Customs clearance documents and assistance?

We provide invoices, packing lists, certificates of origin, CE reports, etc. free of charge. Our team assists with import license applications and provides REACH/FDA compliance guidance.