FamTECH provides 3 types of manure dewater machine: screw type manure dewatering machine, inclined screen type manure dewatering machine, drum type manure dewatering machine. We also provide other manure handling machine such as manure scrapper removal, manure dryer, manure pelletizer for your poultry house.

Manure screw press

Standard Configuration

Separation main machine + Non-clogging submersible pump + Overload protection electric control box + High-quality high-elastic spring clamp

Optional Screen Gaps

0.3MM, 0.35MM, 0.4MM, 0.5MM, 0.7MM, 1.0MM

Material

High-strength spiral shaft, corrosion-resistant alloy double spiral blades (alloy-treated), stainless steel screen; 10mm seamless steel tube shell (high-strength thickened steel)

Parameters of manure screw press

| Model | Production Capacity (m³/h) | Power (Kw) (main motor/water pump) | Overall Dimension (mm) |

|---|---|---|---|

| FMS-180 | 5-8 | 4kw/3kw | 18006001300 |

| FMS-200 | 10-12 | 5.5kw/3kw | 19006001300 |

| FMS-300 | 18-20 | 7.5kw/4kw | 22008001400 |

| FMS-400 | 25-35 | 11Kw/4kw | 250010001600 |

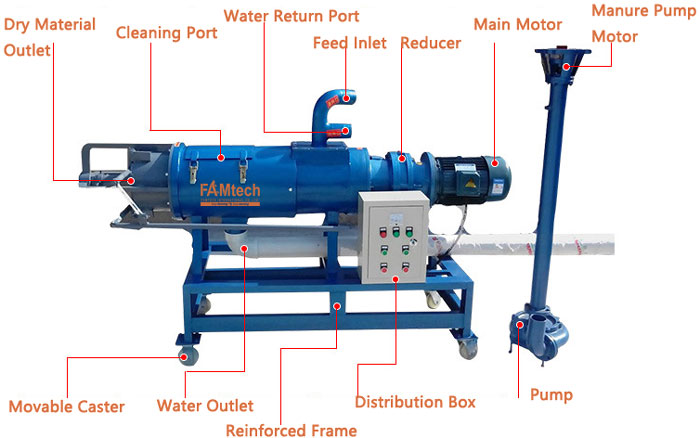

Structure of dewatering screw press for sale

This compact, modular equipment has 4 core parts:

Mainframe: Body, stainless steel screen, high-strength spiral conveyor, vibrating motor & unloader. High-strength spiral shaft, manganese-treated blades and stainless steel screen enable stable, efficient separation.

Auxiliary gear: Non-clogging pump for smooth high-concentration manure/sewage transfer.

Power system: Reduction motor delivers stable, adjustable power for varied needs.

Control system: Dedicated cabinet with simple interface (start/stop, parameter adjustment) for precise control.

Inclined screen manure dewatering machine

Processing capacity

Depending on the type of material, it is 8 to 15 cubic meters per hour for liquid materials and 2 to 5 cubic meters per hour for high-water-content solid materials

Optional filter screen gaps

0.3MM, 0.35MM, 0.4MM, 0.5MM, 0.7MM, 1.0MM

Material

High-strength spiral shaft, wear-resistant alloy double spiral blades, screen is made of stainless steel, spiral blades are treated with alloy, and the shell box is made of 10mm seamless steel pipe with high strength and thickened steel formed in one piece

Core Advantages

Integrated Functions

Combines manure pumping, vibration, slag conveying & extrusion, and automatic flushing systems. It enhances sewage treatment capacity, squeezes manure residue dry for easy utilization, and features a creative design.

Efficient Separation

Adopts vibration separation, enabling fast solid-liquid separation and strong processing capacity.

Environment Adaptability

The design and material selection of the vibrating screen and its support columns are suitable for harsh environments with high corrosion and humidity, and it operates with low noise.

Low Moisture Content

The screw extrusion system performs secondary treatment on manure residue. With a sewage discharge port, the moisture content of manure residue can be reduced to below 60%. The outlet adjustment frame can adjust the moisture content to fermentation humidity, and the dry-wet level is adjustable.

No Secondary Pollution

No leakage occurs during the packaging, transportation, and use of manure residue. Its performance is superior to similar products at home and abroad.

Model Parameters

| Model | Motor (kw) | Processing Capacity (m³) | Machine Weight (kg) | Ex-factory Price (CNY) |

|---|---|---|---|---|

| FMI-200 | 2.2 | 20 | 350 | 22000 |

| FMI-400 | 2.2 | 40 | 480 | 26000 |

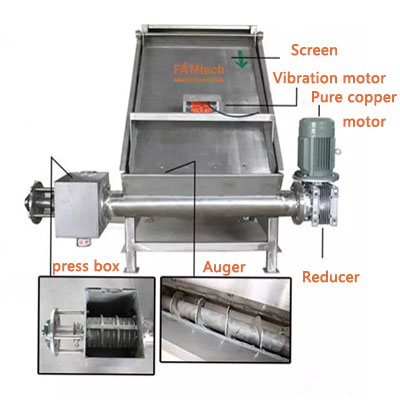

Details of the inclined screen manure dewatering equipment

Stainless Steel Shell – Corrosion-Resistant & Durable

The 304 stainless steel shell is sturdy and corrosion-resistant, featuring a more stable and robust outer structure that is both aesthetically pleasing and long-lasting.

Rotating Auger Blades – Exquisite Craftsmanship

The thickened stainless steel rotating auger blades are sturdy, corrosion-resistant, high-efficiency, and durable for long-term use.

Stainless Steel Screen – Craftsmanship Quality

The 304 stainless steel screen has dense mesh grids for precise filtration, with excellent corrosion and wear resistance.

Adjustable Tightness Discharge Port – Exquisite Workmanship

The discharge port with adjustable tightness is durable and corrosion-resistant, significantly extending the service life of the machine.

Drum type dewatering press for sale

Advantages of the Drum Manure Dewatering Machine

Flexible Adaptability: Available in 1500 and 2000 models with sizes suitable for different spaces; drum and screen specifications correspond to different processing capacities.

Reliable Power: Core components use pure copper motors (2.2kW variable-frequency drum motor, 5.5kW extruder motor), featuring strong magnetic induction, high melting point, and long service life.

Precise Speed Regulation: Stepless speed regulation drum + pure copper stepless speed motor allow adjusting filtration speed based on processing conditions, and dewatering speed based on manure saturation.

Efficient Dewatering: Professional dense mesh (20/200 mesh, adjustable gap) adapts to different particles; the enlarged and extended extrusion bin provides high pressure, ensuring fast discharge and full dewatering.

Parameter Table of Drum Manure Dewatering Machine

| Item | 1500 Model Specification | 2000 Model Specification |

|---|---|---|

| Equipment Dimensions | 2.2m (L) × 1.9m (W) × 1.6m (H) | 2.7m (L) × 1.9m (W) × 1.6m (H) |

| Drum Dimensions | 700×1500 | 800×2000 |

| Drum Motor | 2.2kW variable-frequency motor (pure copper) | 2.2kW variable-frequency motor (pure copper) |

| Extruder Power | 5.5kW | 5.5kW |

| Pump Parameters | 4kW, 1500 | 4kW, 1500 |

| Spiral Extrusion Screen Size | 180×600 | 180×600 |

| Screen Specification | 20/200 mesh (adjustable gap) | 20/200 mesh (adjustable gap) |

| Extrusion Bin Configuration | Enlarged & extended type | Enlarged & extended type |

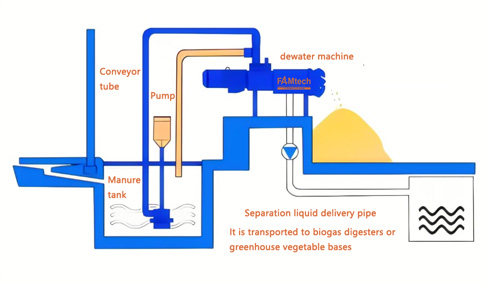

What is manure dewater machine?

Manure dewater machine is an environmental protection device specially designed to solve the pollution control and resource recovery of intensive aquaculture. Its core function is to achieve efficient separation of high-concentration organic wastewater and solid residues.

It is not only applicable to the treatment of various livestock and poultry manure such as chicken, pig, cattle and horse, but also can be widely used in the separation of sludge and liquid of various high-concentration organic wastes such as pulp, distiller’s grains, medicinal residue, starch residue, sauce residue, kitchen waste and slaughterhouse wastewater.

The dewatering machine, through scientific separation processes, converts the originally environmentally polluting manure and sewage into reusable liquid and solid organic fertilizers. This not only solves the problem of breeding pollution but also realizes the recycling of resources, contributing to the green and sustainable development of the breeding industry.

Advantages of manure dewatering machine

High and stable performance

The separation speed of sludge and liquid is fast. After separation, the moisture content of the manure residue is controlled at 40-60%, and the removal rates of solid content, chemical oxygen demand, total oxygen consumption, nitrogen and phosphorus can reach 70-95%.

The dewatering machine has strong decontamination ability, no risk of clogging, is easy to clean, and is suitable for the manure and sewage produced by different component feeds. The amount of residue and moisture content can be flexibly adjusted.

Outstanding durability

The core components such as the frame, screen frame and screen mesh are made of stainless steel or have undergone anti-corrosion treatment, which is highly resistant to corrosion and has high strength. The service life of the spiral blades is twice that of similar products, and they are not easily damaged during long-term use, reducing the cost of equipment replacement.

Convenient operation and maintenance

The manure dewatering equipment is compact in size, occupies little space, requires no complex installation process, is easy to operate and understand, and is convenient for daily maintenance. No flocculant needs to be added, reducing the input of chemical agents and lowering the usage cost.

Significant return on investment

The purchase and operation costs of manure dewatering machine are low, and the investment recovery is fast. It can not only save the construction area and investment cost of environmental protection facilities such as biogas digesters and biochemical tanks, but also create additional income through the resource utilization of solid waste.

High resource utilization rate

The solid manure residue after separation has a wide range of uses. It can be directly used as fertilizer or bedding for cattle. When mixed with straw chaff and fermented, it can be made into compound organic fertilizer or pellet feed. It can also be used for fertilizing flowers and special economic crops, improving soil organic matter, and even replacing coal as fuel (with a calorific value of up to 6,000 kcal and an economic cost of only one-tenth of that of coal). Liquid organic fertilizer can be directly used for irrigation and fertilization of crops, achieving the recycling of nutrients.

Applications of manure dewatering machine

Livestock and poultry breeding: Applicable to various intensive breeding farms such as chicken farms, pig farms, cattle farms, and horse farms, it can handle chicken manure, pig manure, cattle manure, horse manure and other livestock and poultry manure, solve the problem of manure pollution, and realize the resource utilization of breeding waste.

Agricultural product processing: It can handle by-products of agricultural product processing such as distiller’s grains, medicinal residues, starch residues, and sauce residues. The separated residues can be reused, and the treated wastewater can be discharged up to standard or recycled.

Kitchen waste and slaughterhouse: It is used for the separation of sludge and liquid in kitchen waste and high-concentration organic wastewater from slaughterhouses, reducing pollutant emissions and alleviating environmental pressure.

Other environmental protection: It can handle industrial organic wastewater such as pulp and various high-concentration organic wastes, and is widely used in environmental protection governance, resource recycling and other fields, helping various industries achieve green production.