Egg grading machine

Egg grading machine is a mechanical equipment used for automatically sorting eggs according to their weight, size, color, surface cleanliness, cracks and other indicators. It is widely used in poultry egg processing plants, farms and food enterprises.

FamTECH provides 3 solutions of egg grading machines for sale: semi-automatic, automatic, multi-functional integrated solutions with capacity of 2000-30,000+ eggs/h(customized)

Small grading machine–semi auto/auto

Manual feeding, equipment to complete the sorting, suitable for small farms.

Learn the details

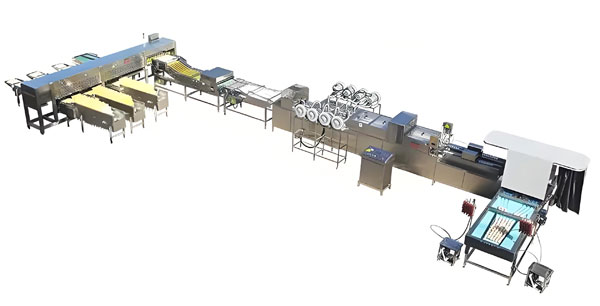

Full-automatic grading line

The whole process from washing, drying, testing to grading is automated, with high efficiency.

Learn the details

Multi-function all-in-one machine

Integrated cleaning, sterilization, grading, spraying code and packing.

Learn the detailsFamTECH also provides other poultry equipment such as automatic egg collection system, egg incubator, poultry drinker, poultry feeder, manure removal system, manure dryer

Small-scale egg grading machine — semi-automatic/automatic

Small scale egg grading machine is very simple to operate, the operator (1-2) will put the eggs on the conveyor line, the equipment can be according to the weight size of the eggs, automatically sent to different collection baskets, the equipment has a reliable performance, easy to operate, high efficiency, grading process of the eggs are not easy to break the characteristics.

Grading accuracy (6-12 grades) and production capacity (2000-10,000 eggs/hour) can be customized according to customer requirements.

Features of FamTECH’s small-scale egg grading machine

Structural design

Adopting 304 stainless steel frame, both lightweight and high-strength characteristics.

Industrial-grade appearance design, in line with food hygiene standards

With a standardized interface design, maintenance time is reduced by 40%.

Key components life ≥ 1 million cycles.

Core performance

Modularized design ensures complete interchangeability of parts

Patented knife conveyor system with lever weighing mechanism.

Weighing accuracy up to ±0.5g, supports quick calibration.

Transmission system

Innovative eccentric sprocket + compensating sprocket double transmission structure.

Transmission efficiency increased by 30%, energy consumption reduced by 15%.

Transmission system

Cam gear linkage system for lossless weighing.

Self-correcting rubber wheels for automatic orientation of eggs

Pass-through optical detection unit (optional configuration):

– Blood spot recognition rate ≥ 98

-Crack detection accuracy ≥99%

Advantages of small-scale egg grading machine

High degree of automation: the equipment can automatically complete the grading of eggs, reducing manual intervention and improving production efficiency.

High grading accuracy: the high precision of sensor and controller ensures the accuracy of egg grading.

Easy operation: the operation interface of the equipment is friendly, easy to learn and master, reducing the difficulty of operation.

Convenient maintenance: the equipment is reasonably designed, easy to clean and maintain, prolonging the service life.

Full-automatic egg scale egg grader — washing, drying and oil spraying

Details of the automatic egg grading machine

Automatic egg loading machine

Adopting vacuum adsorption system to realize non-destructive grabbing and transferring of eggs.

Automatic stacking of empty egg trays, reducing manual intervention and improving production efficiency.

Suitable for a variety of egg tray specifications (plastic/paper), strong compatibility.

Egg collection buffer table

Centralized storage of eggs to ensure continuous and stable feeding.

Adjustable buffer capacity to meet different production needs.

Intelligent Cleaning System

Food-grade flexible brush, gentle cleaning of eggshell surface stains.

Variable frequency speed control (0-60Hz), adapting to different cleaning needs.

Spraying + brushing double cleaning to ensure high cleanliness.

Multi-directional air drying system

Layout of three-dimensional air nozzles, blow-drying the waist, big head and small head of eggs in all directions.

Low temperature and constant pressure airflow to avoid damage to eggs due to high temperature.

Rapid drying, reduce moisture residue.

UV sterilization module

265nm UV sterilization, inactivate microorganisms on the surface.

In line with food processing hygiene standards, sterilization rate ≥ 99.9%.

Atomization oiling system

High-pressure atomized spraying, the oil film evenly covers the surface of eggshells.

Oil mist recycling device, reduce waste, reduce operating costs.

The oil volume can be precisely adjusted to meet different preservation needs.

Optical Inspection Unit

Multi-spectral transmission detection, recognizing defects such as cracks, blood spots, spoiled eggs, etc.

Automatic rejection of defective products, accuracy ≥ 99%.

Support data recording, easy to trace the quality.

Intelligent grading system

High-precision dynamic weighing, grading error ≤±0.5g.

5-8 levels adjustable (set according to customer demand).

Automatic directional arrangement ensures that the big head of the egg is facing upwards, which is convenient for packaging.

Grading speed up to 8000-30,000 eggs/hour (higher capacity can be customized).

Full-automatic egg grading machine — washing, drying, disinfecting, coding, packing

Details of the automatic egg grading machine

Automatic egg loading by robot arm

Vacuum suction cup gripping system for gentle and damage-free transfer of eggs to the conveyor rollers.

Adaptation to different egg tray sizes (plastic/paper), strong compatibility.

Precise positioning ensures the eggs enter the production line smoothly.

Brush cleaning system

Food-grade flexible brushes with warm water spray (35-45℃ adjustable).

Efficiently removes egg shell surface stains, cleaning rate ≥99%.

Frequency conversion speed control (0-60Hz), adapting to different cleaning needs.

Intelligent drying system

Low temperature strong wind drying technology (30-50 ℃ adjustable), rapid removal of surface moisture

Multi-angle air nozzle design ensures the eggs dry evenly.

Avoid high temperature affecting the quality of eggs

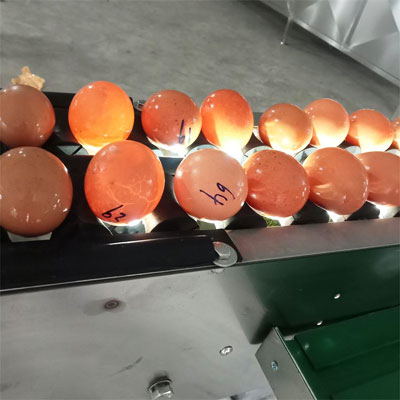

Transparent light inspection station

High-brightness LED light source realizes translucent detection of eggs.

Manually assisted to remove the unfresh eggs, blood spots, cracked eggs and other defective products.

UV sterilization system

High-intensity UV lamps (265nm wavelength), efficient sterilization.

In line with food hygiene standards, sterilization rate ≥ 99.9%

Printing code marking station

Reserve high-precision coding interface, support for laser/inkjet printing

Can be labeled production date, batch number, brand LOGO and other information

Optional automatic inkjet printer (customized solution)

Patented oil spraying system

Atomized spraying technology (national patent), forming a uniform protective film

Freshness preservation liquid can be customized (mineral oil/vegetable-based), prolonging the shelf life of egg products

Oil mist recycling device, reduce waste, environmental protection and energy saving

Electronic intelligent grading system

High-precision dynamic load cell, grading error ≤±0.5g

Programmable grading standard (5-8 levels adjustable), support gram customization

Real-time statistics, record the quantity and production efficiency of each level.

Touch screen control, flexible adjustment of parameters

Fully automatic packaging system

Eggs are automatically transported to the corresponding packing line after grading.

Manipulator/guide device precisely loads the egg trays to ensure that the heavy head is facing upwards.

Support various packing specifications (6pcs/12pcs/18pcs etc.)

Egg grading machine price

| Equipment Type | Price Range (USD) | Grading Criteria | Capacity (eggs/hour) | Key Features | Application Scenario |

| Semi-Automatic Grader | 700–4,200 | Weight/Size | 200–500 | Basic weighing, manual feeding | Small farms, homesteads |

| Basic Automatic Grading Line | 7,000–21,000 | Weight + Crack/Stain Detection | 1,000–3,000 | Auto-feeding, optical surface inspection | Medium-scale egg producers, cooperatives |

| High-End Automatic Grading Line | 21,000–70,000 | Weight + Internal Defects (Blood Spots, etc.) | 5,000–20,000 | Full automation (cleaning, drying, grading, packaging) | Large egg processing plants, export-oriented businesses |

| Premium Imported Grading Systems | 70,000–210,000+ | AI-Based Full Inspection | 30,000+ | Ultra-high speed, 360° AI vision, modular expansion | Multinational corporations, premium egg exports |