A commercial egg incubator is a machine designed to simulate the hatching environment for birds. By controlling parameters such as temperature, humidity, and ventilation, it assists in the hatching process of bird eggs.

Why choose Famtech’s commercial egg incubator

Ensure precise and dependable temperature and humidity regulation with our advanced imported temperature and humidity sensors, guaranteeing optimal conditions for your hatchery needs.

Rely on our stable and trustworthy automatic egg turning mechanism, coupled with automated temperature and humidity controls, to streamline the incubation process and maximize hatch rates.

Experience superior airflow management with our scientifically designed circulation ventilation system, maintaining consistent environmental conditions throughout the entire incubation process.

Comes with matching egg trays and hatching trays (chicken, duck, goose, pigeon, quail, indigenous chicken, wild duck, turkey, goose, peacock egg trays available for selection).

Unlock versatile hatching capabilities with our innovative microcomputer control system, enabling multi-mode functionality to accommodate a diverse range of egg types within a single incubator.

Advanced ultrasonic atomization technology for enhanced humidity stability.

The cabinet is assembled using colorful steel plates, presenting an aesthetic and elegant appearance.

The incubation equipment is multi-purpose in one. It has automatic temperature control, automatic humidity control, automatic egg turning, automatic ventilation, alarm and other functions. It can realize over-temperature, over-humidity, low temperature and low humidity, and can automatically start temperature exhaust and dehumidification according to the changes in the environment inside the machine. , Heating and constant temperature humidification equipment.

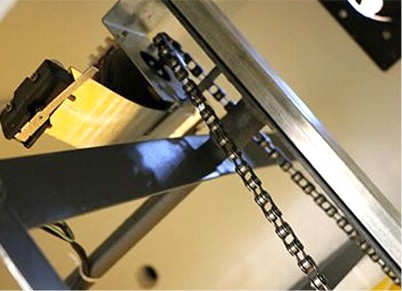

Automatic Egg Turning System

Internal wiring is all copper, durable, reliable. One-key automatic incubation, intelligent, uniform egg turning. Stable speed, no egg damage.

Temperature and Humidity Sensing System

Accurate measurement of temperature, humidity. Safeguards your incubation journey.

Humidification Water Tray

Automatically stops when water is full, with a humidification tube to prevent dryness, maintaining internal moisture and a safety operation.

Automatic Circulating Air Control

Unique air circulation heating system ensures internal air circulation, increasing the success rate of incubation.

Designed Temperature Fans

Ensures even heating in every corner, regulate the temperature and humidity in time. High quality raw material makes sure long-term usage.

Multi-layer incubator tray

Able to hatch 32-56k eggs simutaneously, greatly increased the economic efficiency, the automatic system reduces the cost of labor.

Parameters of our commercial egg incubator

Maximum capacity reaches 56k+ eggs

| Capacity(Pcs per set) | Electric heating power(W) | ||||||

| No. | Scale | Chicken egg | Duck egg | Goose egg | Pigeon egg | Quail egg | |

| 1 | Small Scale | 88 | 63 | 32 | 112 | 221 | 700 |

| 2 | 176 | 128 | 64 | 224 | 442 | 700 | |

| 3 | 264 | 189 | 96 | 336 | 663 | 700 | |

| 4 | 352 | 252 | 128 | 448 | 884 | 700 | |

| 5 | 440 | 315 | 160 | 560 | 1105 | 700 | |

| 6 | 528 | 378 | 192 | 672 | 1326 | 700 | |

| 7 | 880 | 630 | 320 | 1120 | 2210 | 1000 | |

| 8 | 1056 | 756 | 384 | 1344 | 2652 | 1000 | |

| 9 | 1232 | 882 | 448 | 1568 | 3094 | 1000 | |

| 10 | 1408 | 1008 | 512 | 1792 | 3536 | 1000 | |

| 11 | 1584 | 1134 | 576 | 2016 | 3978 | 1600 | |

| 12 | 1848 | 1323 | 672 | 2352 | 4641 | 1600 | |

| 13 | Medium Scale | 2112 | 1512 | 768 | 2688 | 5304 | 1600 |

| 14 | 2376 | 1701 | 864 | 3024 | 5967 | 1600 | |

| 15 | 2640 | 1890 | 960 | 3360 | 6630 | 1600 | |

| 16 | 2816 | 2016 | 1024 | 3584 | 7072 | 1600 | |

| 17 | 3168 | 2258 | 1152 | 4032 | 7956 | 1600 | |

| 18 | 3520 | 2520 | 1280 | 4480 | 8840 | 1600 | |

| 19 | 3872 | 2772 | 1408 | 4928 | 9724 | 2000 | |

| 20 | 4224 | 3024 | 1536 | 5376 | 10608 | 2000 | |

| 4576 | 3276 | 1664 | 5824 | 11492 | 2000 | ||

| 22 | 5280 | 3780 | 1920 | 6720 | 13260 | 2000 | |

| 6336 | 4536 | 2304 | 8064 | 15912 | 2000 | ||

| 23 | 8448 | 6048 | 3072 | 10752 | 21216 | 3200 | |

| 24 | Large Scale | 9856 | 7056 | 3584 | 12544 | 24752 | 3200 |

| 25 | 12672 | 9072 | 4608 | 16128 | 31824 | 4800 | |

| 26 | 14784 | 10584 | 5376 | 18816 | 37128 | 4800 | |

| 27 | 16896 | 12095 | 6144 | 21504 | 42432 | 6400 | |

| 28 | 19712 | 14112 | 7186 | 25088 | 49504 | 6400 | |

| 29 | 22528 | 16128 | 8192 | 28672 | 56576 | 6400 | |

How does the commercial egg incubator work?

Temperature Control

The commercial egg incubator is equipped with a thermostat or temperature sensor internally, enabling real-time monitoring and control of the temperature in the incubation chamber. Depending on the hatching requirements of different bird species, temperature settings can be adjusted to ensure it remains within the appropriate range, providing an ideal hatching environment.

Humidity Control

Embedded with humidity sensors and humidity regulation devices, the commercial egg incubator can automatically adjust the humidity in the incubation chamber. Different bird species have varying humidity requirements during the hatching process. For example, pigeons and quails require higher humidity, while sparrows prefer lower humidity. The commercial egg incubator can adjust humidity accordingly to meet the needs of the incubating bird eggs, providing suitable hatching humidity.

Ventilation System

Equipped with a ventilation device internally, the commercial egg incubator can circulate air, maintaining fresh air within the incubation chamber. The ventilation system also regulates the concentration of carbon dioxide inside the incubation chamber, ensuring the respiratory needs of the bird eggs are met and providing a conducive growth environment.

Hatching Trays and Automatic Egg Turning Mechanism

The commercial egg incubator is fitted with hatching trays capable of accommodating multiple bird eggs. Some incubators also feature automatic egg turning mechanisms, simulating the action of a mother bird turning eggs, thereby aiding in even heat distribution and increasing the hatching success rate.

Applications of commercial egg incubator

An egg incubator can be used to hatch various types of eggs, depending on the specifications of the incubator and the desired outcome. Common eggs that can be hatched in an incubator include:

Chicken eggs: Perhaps the most common type of egg hatched in incubators, used by both hobbyists and commercial poultry farmers.

Duck eggs: Ducklings can also be hatched in an incubator, with similar temperature and humidity requirements to chicken eggs.

Quail eggs: Smaller eggs like those of quails can also be successfully hatched in many incubators.

Turkey eggs: Larger poultry eggs, such as those from turkeys, can also be hatched in specialized incubators with appropriate settings.

Goose eggs: Incubators with larger capacities and adjustable settings can accommodate the larger size of goose eggs.

Pheasant eggs: These eggs require specific conditions for successful hatching, but many incubators can provide those conditions.

Parrot or other exotic bird eggs: Specialty breeders may use incubators to hatch eggs from various exotic bird species.

Reptile eggs: Some reptile breeders use incubators to hatch eggs from species like snakes, lizards, and turtles, although the requirements may differ from those of bird eggs.

FAQ

Q: How will the shipment be arranged?

A: The shipment will be conducted by sea from Qingdao port, China.

Q: What packing method is used?

A: The goods will be packed in wooden cases. If the entire container is loaded, soft packing will be used inside.

Q: What is the estimated delivery time?

A: The delivery time is expected to be 20-30 days after receiving your prepayment.

Q: What are the payment terms?

A: Payment terms require a 30% prepayment in advance via T/T, with the remaining 70% to be paid before shipping.

Q: How long is the quotation valid?

A: The quotation is valid for 30 days from the date it was offered.

Q: What are the terms of the quality guarantee?

A: The quality guarantee lasts for one year. Malfunctions caused by the machine itself or quality issues will be covered by us. However, the guarantee does not include wear and tear parts. Other malfunctions which are caused by electric power supply, operation mistakes which are not following our instructions, unauthorized modification to machine or parts, or other man-made problems, etc will be responsible by user self.

How to use the commercial egg incubator correctly

1. Pre-Incubation Preparation

Before installation, ensure the cement floor is level. The incubator should be tilted slightly forward (or some models backward) for easy drainage during cleaning. Leave 2-3 meters of operating space in front of the machine door.

Disinfection of the incubation chamber should be carried out one week before incubation. Clean all corners of the incubation chamber thoroughly and disinfect using potassium permanganate and formaldehyde.

One week before incubation, systematically check the installation for stability and ensure the accuracy and reliability of all electrical system connections.

Ensure the incubation chamber is tightly closed after inspection. Check for any deformations in the walls, ceiling, or floor of the incubation chamber, and repair any issues promptly.

During the trial run, check the temperature supply, humidity supply, alarm bell, fan systems, and the rotation of motors. After confirming everything is in order, the trial run can continue for 1-2 days before formal incubation. For pre-incubation preparation of eggs, select eggs based on external observation, egg candling, and egg dissection. Additionally, preheat and disinfect eggs before incubation.

2. Incubation Management

Egg incubation

Eggs placed on trays should undergo preheating and disinfection before incubation. When placing eggs into the incubator, insert the egg trays into the egg racks. Ensure the balance of the egg racks to prevent egg turning.

Temperature adjustment and ventilation

Once temperature is adjusted and fixed, avoid further adjustments. Initially, due to opening the door to place eggs, there will be a loss of heat, resulting in a rapid temperature drop inside the incubator. This is normal, and the temperature will gradually return to normal over time. If the temperature inside the machine deviates by ±0.5°C, investigate and adjust accordingly. Observe the temperature indicated by the thermometer on the door at all times. Increase ventilation as embryos develop, and fully open vents in later stages to meet the oxygen needs of the embryos. However, avoid excessive opening of vents in the early stages to prevent slow heating and energy waste. Generally, the temperature inside the incubator is required to be around 38°C during incubation from days 1 to 19. When transferring eggs to the incubator, the incubator’s temperature should not exceed 37.5°C. When using the incubator, ensure to follow the recommended temperature settings in the manufacturer’s manual, considering environmental conditions.

Humidity Regulation

The ideal relative humidity inside the incubator is 53%-57%. During incubation, regularly monitor the dry and wet bulb thermometers on the glass window of the incubator. Additionally, water in the reservoir of the dry and wet bulb thermometers should be replaced frequently.

Egg Turning

Eggs should be turned every 2-3 hours at an angle of ±45°. If controlling multiple incubators simultaneously, it is advisable to have all incubators turn eggs in the same direction. Record egg turning activities each time.

3. Management in the Later Stage of Incubation

Around 18-19 days into incubation, embryos should be transferred to a incubator for continued incubation until hatching. When transferring eggs, the room temperature should be increased, and the handling should be gentle, steady, and quick. Around 20.5 days into incubation, a large number of chicks will begin to hatch by pecking through their shells. When more than 30% of the eggs have hatched, start removing chicks with mostly dry feathers and discard eggshells. Keeping chicks with wet feathers in the incubator for too long or examining chicks when their feathers are not yet dry can both affect the health of the chicks. After hatching is complete, it is essential to thoroughly clean and disinfect both the incubator and the incubation chamber. Hatching trays and water pans should be cleaned and then subjected to fumigation disinfection inside the incubator after being washed clean.