Chicken feed making machine –key for your poultry farm

The chicken feed making machine is a core feed processing equipment specially developed for poultry farming scenarios.

Through high-temperature extrusion and maturation molding technology, it processes loose feed raw materials into uniform pellet feed.

The equipment features core advantages such as high molding rate, good nutrient retention, convenient operation and low energy consumption.

It can be flexibly matched with different models according to the scale of breeding: family workshops, small and medium-sized farms, large-scale breeding bases and the characteristics of raw materials, meeting the feed requirements of all stages of chicken flocks including laying hens, broilers and chicks.

This reduces breeding costs from the source, improves feed conversion rate and breeding benefits It is an indispensable key equipment for the modern chicken farming industry.

FamTECH also provides other poultry farm equipment such as automatic feeding system, watering system, manure removal, climate control system and so on.

Advantages of FamTECH’s chicken feed pellet machine

Easy Storage and Transportation & Low Power

- Pelleted feed takes up little space, is not easily deformed by extrusion, and is easy to store.

- It is not prone to scattering, reducing feed loss and environmental pollution. It is especially suitable for large-scale, densely stocked livestock farms.

Simple Structure & Improved Feed Utilization

- Processing raw materials of different types, shapes and sizes into uniform pellets through grinding, mixing, pressing and other processes. This enables animals to absorb and utilize the nutrients more fully.

- Pelleted feed is easy to digest and absorb, which improves animals’ feed utilization rate and thus reduces feed costs.

High-Quality Pellets & Efficient Production

- High-efficiency feed pellet machine (extrusion granulation: dry in/out, no drying needed)

- Low energy use, high output, easy operation

- High automation: simple, labor-saving, boosts efficiency

- Advanced granulation tech (chamber pressure control) ensures precise, flat, hard pellets

- Real-time monitoring via auto control system

Details of our chicken pellet making machine

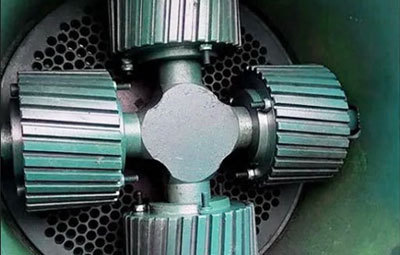

Advanced craftsmanship

Based on the principle of circular motion, the templates and pressure rollers are made of high-quality alloy steel and processed by special forging heat treatment.

High product quality

The pellets processed by this machine have a smooth surface, moderate hardness, and deep internal ripening. It can also kill pathogenic microorganisms and parasites, thus ensuring feed quality

Granulator die plate

High-quality steel with computerized layout drilling is used, followed by quenching treatment for higher wear resistance.

Adjusting nut

Adjust the distance between the pressure roller and the grinding disc to avoid damaging them.

Compact structure

The whole machine has a compact structure, reasonable layout, stable operation and low energy consumption.

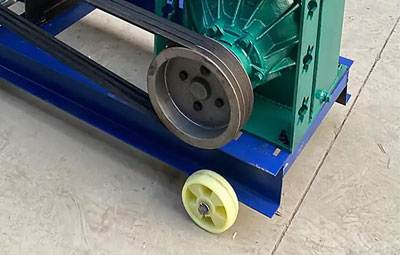

Nylon caster

Nylon casters are adopted, which are wear-resistant, easy to use and convenient to move.

Raw material for chicken feed pellet

Grains: corn, wheat, sorghum, barley, oats, etc. (can be crushed for use).

Protein types: soybean meal, cottonseed meal, rapeseed meal, fish meal, bone meal, silkworm pupa meal, feather meal, etc.

Energy supplements: bran, rice bran, secondary flour, distiller’s grains, beet pulp, etc.

Minerals and additives: stone powder, shell powder, calcium hydrogen phosphate, vitamin premixes, probiotics, fungicides, etc.

Green feed: alfalfa meal, corn stalk meal, peanut stalk meal, etc. (Moisture content needs to be controlled).

The raw materials need to be crushed in advance to 20-40 mesh, and the moisture content should be controlled at 12%-15% to ensure the particle formation effect and storage stability.

Advantages of chicken feed produced by chicken feed making machine

Uniform shape: The particle diameter can be customized (2-8mm), and the length can be adjusted from 3 to 10mm. It is dust-free and does not form lumps, which is convenient for chicken flocks to feed and reduces feed waste (the waste rate is reduced by more than 30%).

Balanced nutrition: The high-temperature maturation process (85-95℃) can destroy anti-nutritional factors, enhance the digestion and absorption rate of nutrients such as protein and starch (15%-20% higher than that of powdered feed), and at the same time achieve sterilization and disinfection, reducing the risk of disease in the chicken flock.

Convenient storage: Pellet feed has a low moisture content (≤12%), is less prone to mold, and has a shelf life 2-3 times longer than that of powdered feed. It is also easy to transport and stack, saving storage space.

Excellent palatability: The matured pellet feed has a rich aroma, which can stimulate the appetite of the chicken flock, increase feed intake, and promote growth and development as well as improve egg production performance (the egg production rate of laying hens increases by 5% to 8%, and the market cycle of broilers shortens by 7 to 10 days).

Parameters of chicken feed machines

Semi-enclosed motor type

| Model | Power Configuration (kW) | Feed Output (kg/h) | Weight (kg) | Packaging Dimension (mm) |

| ZLSP-S 120B | Three-phase 3 / Single-phase 2.2 | 60-100 | 80/100 | 750320680 |

| ZLSP-S 150B | Three-phase 4/5.5 | 90-120 | 95/110 | 800450700 |

| ZLSP-S 200B | Three-phase 7.5 | 200-300 | 200/230 | 1050480930 |

| ZLSP-S 230B | Three-phase 11 | 300-400 | 290/320 | 11805401000 |

| ZLSP-S 260B | Three-phase 15 | 400-600 | 320/360 | 1240540950 |

| ZLSP-S 300B | Three-phase 22 | 600-800 | 410/450 | 13005601100 |

Full-enclosed motor type

| Model | Matching Power (kW) | Feed Output (kg/h) | Weight (kg) | Packaging Dimensions (mm) |

|---|---|---|---|---|

| ZLSP-S 150C | Three-Phase 4 | 90-120 | 105/125 | 1000480780 |

| ZLSP-S 200C | Three-Phase 7.5 | 200-300 | 210/230 | 1050550830 |

| ZLSP-S 230C | Three-Phase 11 | 300-400 | 290/320 | 1200560950 |

| ZLSP-S 260C | Three-Phase 15 | 400-600 | 340/370 | 12405801000 |

| ZLSP-S 300C | Three-Phase 22 | 600-800 | 425/465 | 13006201100 |

Gasoline engine type

| Model | Configured Power (HP) | Feed Output (kg/h) | Weight (kg) | Packaging Dimensions (mm) |

|---|---|---|---|---|

| ZLSP-S 120Q | 7.5 | 60-100 | 120/140 | 900500730 |

| ZLSP-S 150Q | 10 | 90-120 | 180/220 | 1000500750 |

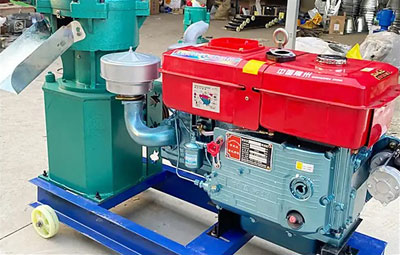

Diesel engine type

| Model | Configured Power (HP) | Feed Output (kg/h) | Weight (kg) | Packaging Dimensions (mm) |

|---|---|---|---|---|

| ZLSP-S 120A | 8 | 60-100 | 120/140 | 900500730 |

| ZLSP-S 150A | 8 | 90-120 | 175/215 | 1000500750 |

| ZLSP-S 200A | 15 | 200-300 | 210/240 | 1460750900 |

| ZLSP-S 230A | 22 | 300-400 | 280/310 | 15608501000 |

| ZLSP-S 260A | 33 | 400-600 | 330/360 | 12005001070 |

| ZLSP-S 300A | 41 | 600-800 | 410/450 | 12206001000 |

Our Factory and product