Drying time: 48 hours

Drying temperature: 20°C

Final product moisture content: 12%-15%

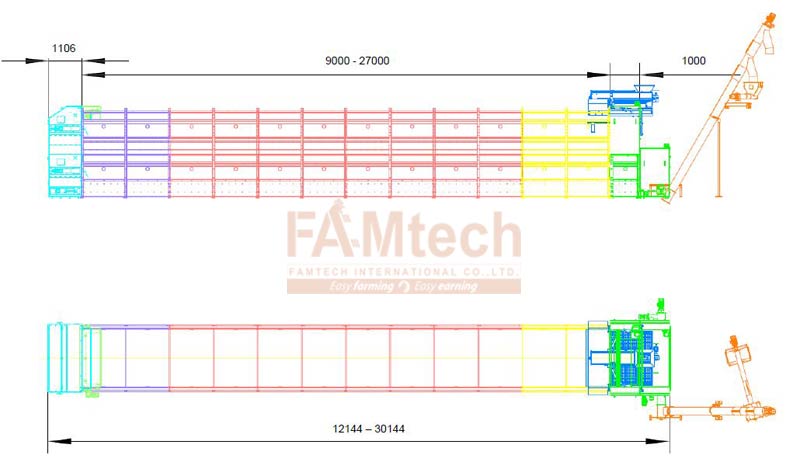

Capacity: 20,000 – 220,000 hens’ manure per dryer

Operation time: 24/7

Maximum ventilation volume: 2.2m³

Size: 31m (length)2m (width)4.2m (height)

Material: high-quality steel & galvanized plank

Customizable: customizable

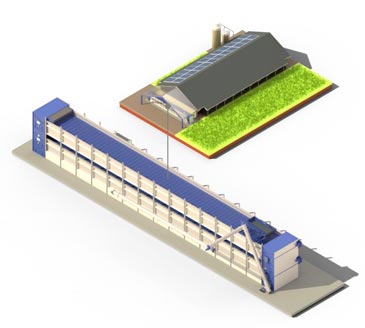

Belt dryer for poultry

With the help of a belt dryer, poultry manure can be dried year-round and converted into organic fertilizer or fuel. Dried poultry manure, whether in dry or pellet form, is an excellent and commonly used plant nutrient.

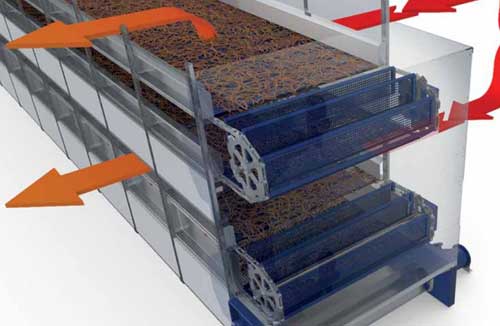

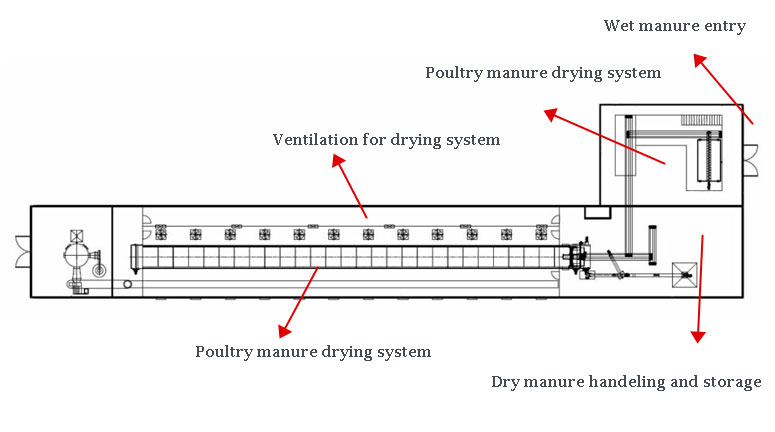

The whole system consists of drying hole plate, driving device, electrical control, conveyor belt for wet chicken manure transportation, and screw conveyor for dry chicken manure transportation. By circulating air, moisture is removed from the chicken manure, achieving rapid drying (typically within about 48 hours).

FamTECH also provides other poultry equipment: egg collection system, egg incubator, manure cleaning equipment

Advantages of FamTECH’s manure dryer

Cost effective

Combines internal farm air with surplus heat from electricity generation for cost-effective drying. 20°C is enough for drying, however, higher temperatures reduce humidity, enhancing the drying process. Poultry manure, in dry or pellet form, is valued for its superior plant nutrients.

Moisture Control

Reducing moisture content from 75% humidity in poultry manure to 12%-15%. Prevents wet manure from sticking to surfaces by mixing it with a small amount of dry manure using specialized equipment.

Durable Construction

Surface treated with hot/cold galvanizing and electrostatic spraying to resist corrosion from poultry manure, prolonging the life of equipment. It is easy maintenance, has simple structure, wear resistance, high temperature resistance, corrosion resistance, and long-lasting durability.

Dust and Ammonia Reduction

Filters air through drying equipment, reducing airborne fine dust by 70%. The system reduces ammonia and particulate matter by 55% at the farm level.

Efficiency and Automation

Operates with low energy consumption, the equipment is fully automated with remote monitoring capability and able to operate nonstop for 24/7. Requires no pre-drying, minimizing dust and optimizing operation efficiency.

Specification of FamTECH’s belt dryer

| Equipment | Power |

| Mixer drive | 2.2 |

| Rotating mixer/belt drive | 0.12 |

| Dryer belt motor | 0.75 |

| Agitator drive | 0.55 |

| Dryer belt motor | 0.75 |

| Scraper auger drive | 0.37 |

| Scraper drive | 0.18 |

| Scraper auger drive | 0.37 |

| Dryer discharge auger | 2.2 |

| Discharge auger 1 | 3 |

| Back-mix auger | 0.75 |

| Discharge auger 2 | 3 |

Manure dryer is customizable

The size of the manure dryer depends on the number of chickens in poultry farm. The number of chickens needed to dry one square meter depends on climate factors, typically ranging from 400 to 600 chickens per square meter. Only a small portion of the heat from the poultry house is lost during the drying process; the rest is efficiently removed from the poultry house. For instance, a dryer designed for 80,000 to 120,000 chickens measures approximately 27 meters in length, 2 meters in width, and 3 meters in height. The professional quality of the manure dryer ensures equipment durability and interference resistance, allowing the system to operate fully automatically without constant monitoring.

FamTECH provides 3 types of chicken manure drying machine

Structure of FamTECH manure dryer

Equipment Main Structure

Hot-dip galvanized treatment ensures durability and corrosion resistance.

Head and tail frames are cold galvanized and spray-coated for enhanced protection against environmental elements.

Equipment Control System

Includes a user-friendly touchscreen interface with a control program for intuitive operation and monitoring.

Manure Plate Conveyor Device

Constructed with cold galvanized and spray-coated materials to withstand the harsh conditions of manure handling.

Ventilation System

Includes a fan control cabinet and high-pressure fan setup for effective airflow management within the drying system, ensuring optimal drying conditions.

Drive Device

Features a robust motor from Italy, renowned for its reliability and efficiency in industrial applications.

Feed and Discharge Devices

Feeding utilizes manure plates, while discharge is managed by a stirring auger to ensure consistent handling of dried manure.

Recycling Device

Utilizes a recycling auger for instances where raw material humidity exceeds 70%, optimizing resource efficiency.

Uniform Feeding Device

Automatically mixes wet and dry components to uniformly distribute moist manure onto the manure plates, optimizing drying efficiency.

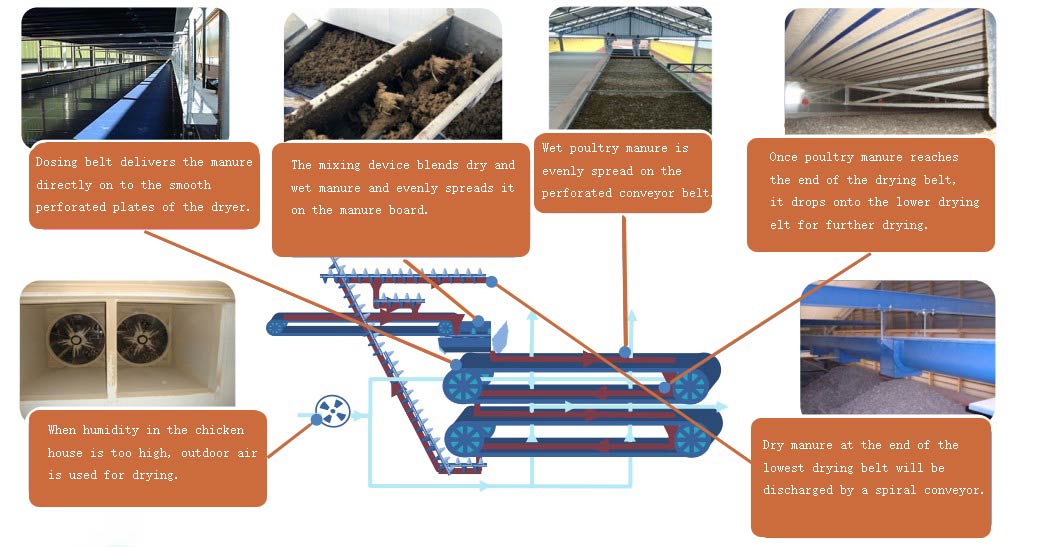

Operation process of the belt dryer

The process begins with fresh chicken manure being transported to the upper section of the chicken manure drying machine using a conveyor belt.

Next, the wet-dry chicken manure mixer blends the manure, which is then evenly spread onto the upper drying board (with a thickness of 15-18 cm).

The driving device moves the drying board forward, allowing the manure to gradually descend onto the lower drying board.

Finally, the dry chicken manure is collected and directed by a screw conveyor for remote transportation. The size of the chicken manure air dryer can be customized based on the number of chickens and available space for installation of the equipment.

Why you need new type of chicken manure drying machine instead of traditional one?

Traditional Drying method of Chicken Manure

Emits exhaust gases and wastewater, causing environmental pollution.

Naturally fermented manure becomes wet and putrid, emitting strong odors and failing to fully ferment.

High moisture content post-fermentation makes storage and transportation difficult.

Natural fermentation inadequately removes harmful substances like pathogens and larvae from the manure.

Fermented chicken manure loses nutritional value, fetching a market price less than half that of air-dried chicken manure.

FamTECH’s chicken manure drying machine

Our equipment features quick installation, high intelligence, low energy consumption, low failure rates, high stability, and long lifespan.

Achieves rapid dehydration, processing fresh chicken manure to ≤15% moisture content within 48 hours.

Prevents the propagation of pests and diseases in the manure, ensuring minimal threat to the environment and human health.

Dried chicken manure is easy to transport and store, reducing costs and conserving resources.

High-quality material post-drying is suitable for producing organic fertilizers or organic materials.

Exhaust gases from air drying meet environmental standards, reducing harmful gas exposure to poultry.

Manure pellet machine you may interested in

The chicken manure drying machine can function stand-alone, or it can be combined with a pelleting plant to create sanitized organic fertilizer pellets. With this solution it is possible to dry, pelletize and sanitize the poultry manure within a period of 3 days.

The pelletizing system is a production line used to process poultry manure into organic fertilizer pellets. Raw materials enter the pelletizing system and are extruded into cylindrical pellets of small volume. This system includes a high-temperature sterilization device for disinfection, effectively eliminating harmful bacteria and pathogens from within the pellets through high-temperature sterilization.

Contact us if you are interested in our pellet machine.

Successful projects of our chicken manure drying machine