A-type chicken battery cage poultry farming

For small poultry farming, FamTECH’s A-type chicken battery cage is the best choice.

Multi-layer structure (3–4 tiers) for maximum space utilization, ideal for large-scale farming

Made of Q235 galvanized material for corrosion and deformation resistance, with a long service life of 10–20 years

Sliding cage door + sloped cage bottom for easier cleaning, chicken catching, egg collection and manure removal

Each cage houses 4 laying hens or 3 broilers, with a load capacity of ≥45kg, fully compatible with a complete set of automated equipment

Integrates seamlessly with feeding, drinking and environmental control systems, cutting feed waste to ≤3% — your top choice for cost reduction and efficiency improvement

Core Cage Selection and Layout

Core Configuration of A-Type Automated Battery Cage System

Cage Specifications: Standard A-type multi-layer cages (3 layers, balancing space utilization and operational convenience) are adopted. The material is Q235 cold/hot-dip galvanized steel wire mesh + U-shaped galvanized frame, with a wire diameter of 2.5mm and mesh size of 50×50mm. It features corrosion resistance, deformation prevention, and a service life of 15–20 years.

Single Cage Dimensions: 1.4m (length) × 0.5m (width) × 0.42m (height). Each cage can house 4 laying hens or 3 broilers, with a load-bearing capacity of ≥45kg. The cage door adopts a sliding design, facilitating chicken catching and cleaning.

Total Cage Quantity: 5,000 chickens ÷ (3–4 chickens per cage) ≈ 1,389 single cages, arranged in 20 columns (69–70 cages per column). The column spacing is 0.75m, and the distance from the cage bottom to the ground is 0.9m, reserving a manure disposal channel.

Cage Layout Planning

Breeding Area Division: A single chicken house is divided into 4 breeding units, with 1,250 chickens per unit. Each unit consists of 5 columns of cages, and the unit spacing is 1.2m (serving as an operation channel). A 1.5m equipment maintenance channel is reserved at both ends of the chicken house.

Cage Inclination Design: The cage bottom is inclined 5° outward. Laying hen cages are equipped with egg rolling troughs (12cm wide, 12° inclination angle), while broiler cages are paved with anti-slip mats to prevent chicken injuries.

Battery Cage Poultry Farming Construction and Site Planning

Chicken House Design Parameters

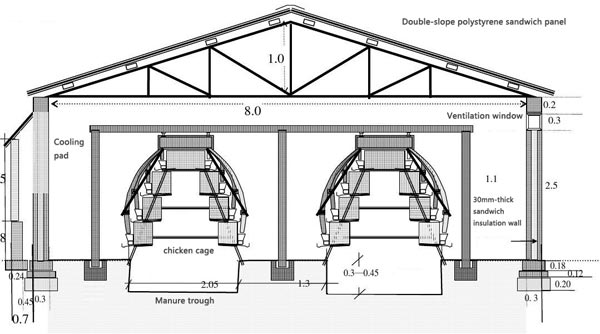

Dimensions: Adapted to the cage layout, the chicken house measures 70m (length) × 10m (width) × 4.2m (height, ridge height 4.2m, eave height 3.0m). The walls are made of color steel plates + thermal insulation cotton (10cm thick), and the roof is double-slope color steel tiles with 5 ventilation skylights (80cm in diameter).

Ground and Drainage: The ground is hardened with C25 concrete (12cm thick) and inclined 3° outward. Drainage ditches (20cm wide, 15cm deep) are set along both sides of the chicken house to avoid water accumulation and cage corrosion.

Disinfection and Isolation: A 3m×1.5m×0.2m disinfection pool is installed at the entrance of the chicken house. A spray disinfection port is set every 20m inside, equipped with ultraviolet disinfection lamps (1 lamp per 15㎡, 30W power).

Site Selection Requirements

Environment: Located at least 500m away from residential areas and water source protection zones. The site should have high and dry terrain, good ventilation, with an annual average wind speed of 2–3m/s, avoiding low-lying and humid areas.

Supporting Facilities: Connected to 380V industrial power supply with power ≥50kW, daily water supply ≥10 tons, and convenient transportation for feed delivery and product output.

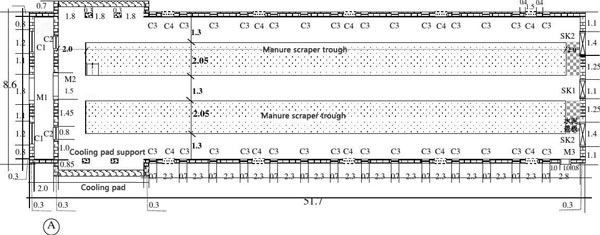

Here is a case of 5000 poultry chicken house

| ID | Height | Width | Top Height | Quantity | Remarks | ID | Height | Width | Top Height | Quantity | Remarks |

|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 2.2 | 1.8 | 2.2 | 1 | Wooden, double door | C4 | 1.6 | 1.5 | 2.2 | 10 | PVC sliding emergency window |

| M2 | 1.8 | 1.5 | 1.8 | 1 | Insulated iron double door | SK1 | 1.1 | 1.1 | 2.8 | 1 | Livestock fan (for box) |

| M3 | 1.8 | 1.0 | 1.8 | 1 | Insulated iron single door | SK2 | 1.4 | 1.4 | 2.8 | 2 | Livestock fan |

| C1 | 1.5 | 1.2 | 2.5 | 2 | PVC double door | Water Mark | 1.5 | 6.0 | 2.3 | 2 | 15cm height paper material |

| C2 | 0.6 | 0.8 | 1.6 | 2 | Fixed observation window | ||||||

| C3 | 0.3 | 0.7 | 2.8 | 28 | Ventilation bottom-hung window |

Note: “Top Height” refers to the height of the installation hole above the floor level

FamTECH provides free design service and turn key service for our customers

Complete Set of Automated Equipment Configuration

Feeding System

- Core Equipment: Imported 30t feed silo from South Africa (equipped with level sensor), MCN motor-driven feed trolley (running speed 0.5m/s, load capacity 400kg), galvanized feed trough (1.4m long per cage, anti-spillage design).

- Operation Logic: Timed feeding 3–4 times a day (3 times for laying hens, 4 times for broilers). Feed is accurately distributed through the process of silo → trolley → conveying track → feed trough. The feeding amount can be adjusted via the controller, with a waste rate ≤3%.

Drinking System

- Core Equipment: Water filter (filtration precision 5μm), DOSATRON chemical dosing pump (mixing ratio range 0.2%–2%), 360° nipple drinkers (2 per cage, uniform water output), V-shaped backup water trough (1 per column of cages, preventing water shortage due to nipple blockage).

- Maintenance Requirements: Clean filters and water troughs weekly; add disinfectant via the dosing pump monthly to ensure the total number of drinking water bacteria ≤100CFU/mL.

Manure Treatment System

- Core Equipment: Imported 1.0mm HDPP manure belt from Italy (1.2m wide, laid under cages), 2 sets of MCN motor-driven galvanized scrapers, manure dryer (processing capacity 300kg/h, reducing manure moisture content to 12%–15%).

- Operation Process: After manure falls onto the manure belt, scrapers convey it to the manure collection tank at a constant speed. After drying, the dry manure is recycled as raw material for organic fertilizer, achieving environmental protection and emission reduction.

Environmental Control System

- Core Equipment: Siemens fans (8 units, air exchange rate 1800m³/h per unit), 150mm-thick paper-aluminum composite cooling pads (25㎡ area), automatic air inlet (electrically adjustable opening), temperature and humidity sensors + PLC control system.

- Regulation Standards: The temperature inside the house is controlled at 18–28℃ (≥18℃ in winter, ≤28℃ in summer), humidity 55%–65%, ammonia concentration ≤15ppm, and air exchange rate ≥10 times per hour.

Special Equipment (Configured by Breeding Type)

- Laying Hen Breeding: Equipped with light-duty egg collection system (imported belt from Italy, 40cm wide, 3,000 eggs collected per hour) and semi-automatic egg grader (processing capacity 2,000 eggs/h, grading by weight).

- Broiler Breeding: Additional cage temperature monitoring points (2 per unit) and supporting rapid weighing equipment (range 50kg, accuracy 0.1kg) for fattening monitoring.

Breeding Management and Supporting Guarantee

Breeding Process Specifications

- Chick Placement: Select healthy chicks. Chicks can be reared in A-type chick cages first (10–12 chicks per cage), and transferred to adult A-type cages at 6 weeks of age.

- Feeding Management: Use full-price feed according to growth stages (chick, grower, layer/fattener). Monitor feed stock via silo level sensors to avoid feed shortage.

- Disease Prevention and Control: Clean cage debris daily, conduct disinfection with chickens in the house once a week, and thoroughly clean equipment monthly. Vaccinate against Newcastle disease, avian influenza, etc., in accordance with the immunization program, and equip with 10 isolation cages for sick chickens.

Equipment Maintenance and After-Sales Service

- Daily Maintenance: Check the operation status of fans, motors, and manure belts daily; lubricate transmission parts weekly; test electrical circuits and sensor accuracy monthly.

- After-Sales Support: Enjoy 1-year product warranty (covering core cage components, motors, sensors) and 365-day VIP consulting service. On-site installation guidance and staff training by the manufacturer can be applied for, with a 48-hour response for key equipment failures.

Site Supporting Facilities

- Auxiliary Areas: Plan a 30㎡ feed storage room (adjacent to the feed silo), a 20㎡ egg storage room (exclusive for laying hen breeding, temperature 15℃), and a 15㎡ office and disinfection room.

- Safety Facilities: Equip the chicken house with 10 8kg dry powder fire extinguishers, install smoke alarms, and conduct waterproof treatment for electrical equipment to avoid electric leakage risks.