Lifespan: 30+ years

Certificates: ISO9001, SGS

Cage Material: Q235 wire mesh and co,d/hot galvanized sheet; 275g/㎡ galvanized aluminum wire mesh & 275g/㎡ cold/hot dip galvanized plate

Poultry House: Large-scale(better more than 25,000) poultry chicken house and closed house

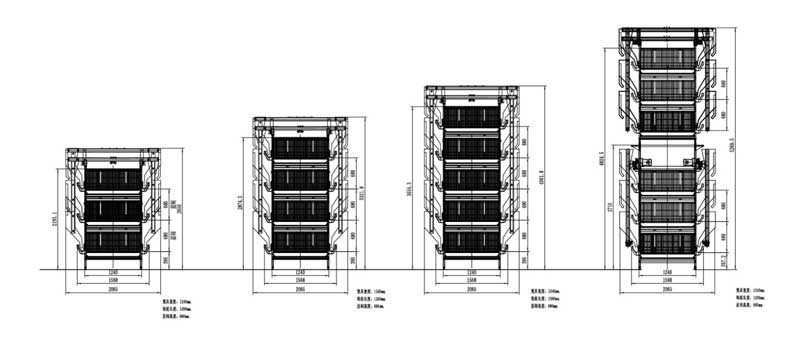

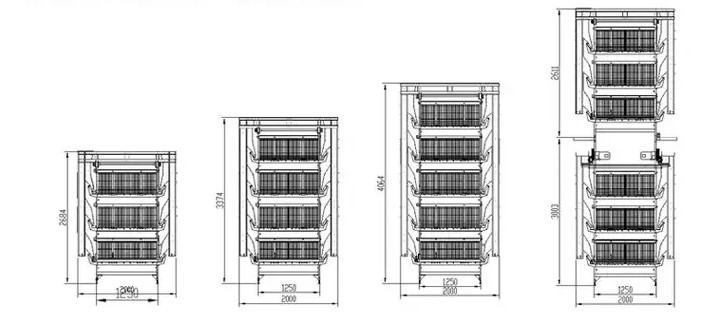

Tiers: 3, 4, 5, 6, 7, 8 (customized according to the height of house and your anticipate farming scale)

Age of birds: From 1 week old -17 weeks

Area for one bird: 310cm²-450cm²

Cell size: 620mm(length)600mm(width)680mm(height)

H type Chick cage

Q235 steel cage wire mesh and cage frame with 275g/m hot galvanization is used to provide smooth surface and ideal elasticity for chicken feet. Little chance of scratch and wound infection.

FamTECH also provides A type chick cage, H type layer cage, H type breeder cage, H type broiler cage

Specification of FamTECH’s chick cage

| Length | Dimension/Cell | Cell/Unit | Birds/Cell | Space/Bird |

| 1200mm | 600*625mm | 2 | 12 | 312.5 cm² |

Details of Famtech’s cage for chicks

High-class cage material and well-designed cage structure give baby chicken a good environment to grow. Heightened cage provide nice ventilation, and the living condition is upgrated furthermore with the aid of supprotive poultry equipment such as feeding system, drinking system, manure system and so on.

Bottom mesh

The plastic bottom mesh of chick cage is high-class, elastic and strong. Its appropriate mesh gap distance can provide enough supporting force to pullet chicken and meanwhile, ensure chicken manure drop to the manure removal belt and keep the baby chicken cages’ floor clean.

Feed intake pedal

Special design of the cage for chicks includes a 9.3cm wide feed intake pedal to facilitate the eating process for baby chicken. This device makes the feed more accessible for pullets.

Feed intake door

The chick cage feed intake door’s height is adjustable along with the change of the size of baby chicken.

There is no obstruction in front of the feed door so the baby chicken can adapt to the cage in a short time.

Cage Material

Q235 steel and Galvan wire and sheet ensure simple maintenance and smooth surface.

Swing door of baby chicken cages allows one-hand operation and easy-check of baby chicken.

Scientifically arranged nipple drinkers are installed in a height-adjustable pipe to fulfill the drinking need of pullet chicken of different ages.

Why choose FamTECH’s cage for chicks?

Professional chicken cage customized design service

FamTECH is a professional chicken cage manufacturer dedicated to providing customers with efficient and durable breeding equipment. We provide free design service, one-on-one personalized design according to customer’s site conditions and breeding needs, to ensure the maximum utilization of chicken coop space and improve breeding efficiency.

Our service advantages

Individualized design: according to the customer’s site size, ventilation conditions, chicken cage structure and other factors, tailor-made optimal breeding program.

High-quality materials: adopt corrosion-resistant, sturdy and durable materials to ensure the long-lasting use of chicken cages and reduce maintenance costs.

Efficient installation support: provide detailed installation guide, support remote guidance, and dispatch technicians to assist installation if necessary.

Successful cases: we have provided professional chicken cage design for many farmers and large farms all over the world, which is highly praised by customers.

Successful case of FamTECH’s H type chick cage

1.2m frame layered chick cage, each set of cage length is 1.2m, single cell width is 600mm, depth is 625mm, total width of cage (left trough to right trough) is 1.56m, total width of traveling feeder is 2m, cage height is 490mm, layer spacing is 690mm, each cage is divided into 2 gates, 12 laying hens can be put into each gate of the chick that has been brooding for 90 days, and the average area occupied by each chicken is 3.2 square centimeters. The average cage area per chicken is 312 square centimeters. The average size of each cage is 312 square centimeters. The capacity of each group is 144 chicks in three tiers and 192 chicks in four tiers.

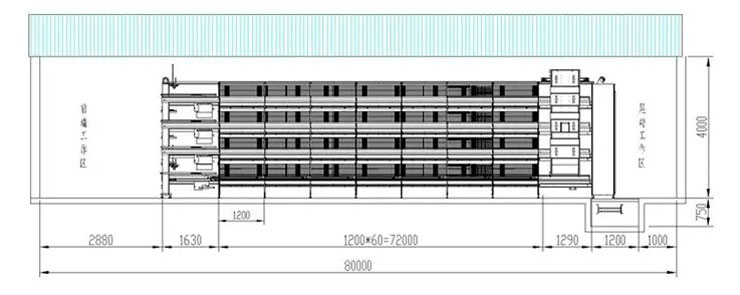

House for chick cage dimensions are recommended for lengths of 80 to 100m and widths of 12.5 to 16m. The picture is based on a length of 80m, a width of 12.5m, four rows and four tiers, and a batch size of 46,080 chicks at 90 days.

The 1.2-meter framed chick cage has a feeder height of 2.684m on the third tier, 3.374m on the fourth tier, 4.064m on the fifth tier, and 5.614m on the sixth tier. The height of the top of the trolley feeder is 24 centimeters above the height of the loading agitator.

Whether you are a small-scale farmer or a large-scale farming enterprise, we can provide you with the most suitable chicken cage solutions. Welcome to contact us for free professional design service!