Poultry Farm Design

FamTECH provides 3 solutions for poultry house plans for 10,000 chickens: battery cage, floor system and aviary systems.

Site Selection and Overall Layout of Poultry Farm

1. Site Selection Requirements

Topography: High and dry terrain with a slope ≤ 5° to avoid waterlogging (prevents disease breeding).

Environment: ≥ 500 meters away from residential areas and water source protection zones, with good ventilation conditions (on the upwind side of the dominant wind direction).

Supporting Facilities: Close to highways (facilitates feed/product transportation), stable power supply (380V industrial electricity required), and sufficient water sources (daily water supply ≥ 5 tons.).

2. Overall Layout (Single Chicken House Design, Replicable for Multi-House Layouts)

Total Floor Area: Approximately 1,500 ㎡ (including main chicken house, auxiliary facilities, and green belts).

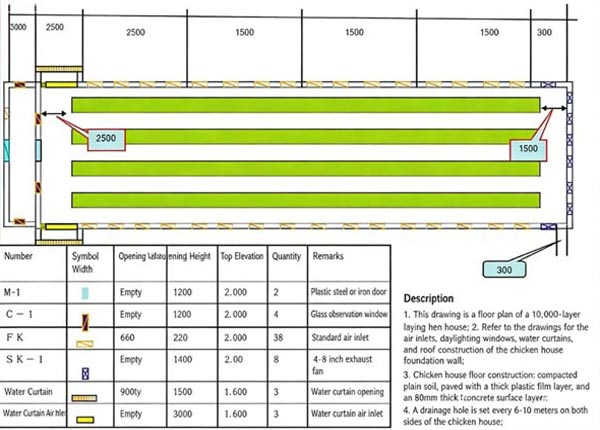

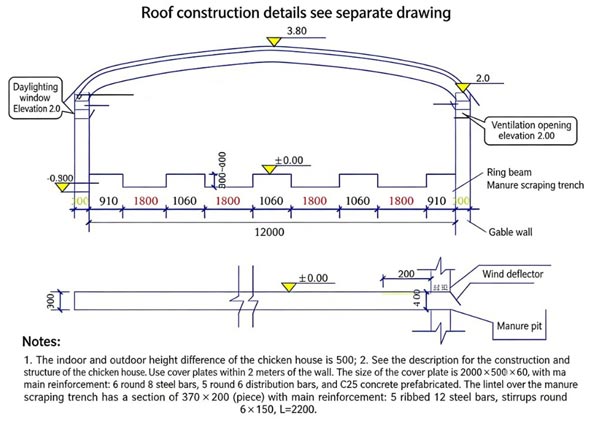

Dimensions of Main Chicken House: Length 80m × Width 15m × Eaves Height 4.5m (Ridge Height 6m), accommodating 10,000 chickens per house (density adapted to different modes, balancing ventilation and activity space).

Auxiliary Facilities: 2 feed silos (20 tons/capacity each), manure treatment area (100 ㎡, including dryer installation space), disinfection area (30 ㎡), control room (20 ㎡), and emergency passages (1.5m wide, set along both sides of the chicken house).

Design of Main Chicken House Structure

1. Structure Type: Light Steel Structure + Composite Insulation Panels

Frame: Hot-dip galvanized steel pipes (column spacing 3m, beam spacing 1.5m), wind load resistance ≥ 0.55kN/㎡, snow load resistance ≥ 0.3kN/㎡, referencing FamTECH’s stable cage structure design.

Enclosure: Double-sided color steel sandwich panels (flame-retardant polyurethane core, thickness 100mm, thermal conductivity ≤ 0.024W/(m·K)) with excellent sealing performance (prevents air and water leakage).

Floor: C25 concrete pouring (thickness 12cm) with anti-slip surface; 1.5% slope towards the manure cleaning side for cage and floor-rearing areas; slatted floors laid in aviary system areas (2m manure passage reserved below).

Doors and Windows: Automatically opening/closing ventilation windows on side walls; sliding doors at both ends (3m wide × 2.5m high, facilitating equipment entry and exit).

2. Breeding Mode Options (Three Modes for Different Needs)

| Breeding Mode | Suitable Poultry | Core Configuration | Density Standard | Advantages |

|---|---|---|---|---|

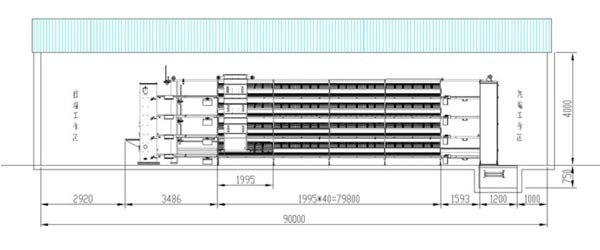

| Battery Cage System (Type A/H) | Layer Chickens/Broilers | 4-tier 3-row cages made of Q235 galvanized material (cage dimensions: 1.8m × 0.6m × 0.5m), equipped with automatic egg collection, manure cleaning, and feeding systems, complying with FamTECH’s standardized cage design (service life 15-20 years) | Layers: 7-8 birds/㎡, Broilers: 8-10 birds/㎡ | High space utilization, high automation, low disease transmission risk, suitable for large-scale production |

| Floor Rearing + Fermentation Bed | Broilers/Local Chickens | 40cm-thick fermentation bed litter (sawdust + rice husk + microbial agents), matched with galvanized feed troughs, 360° nipple drinkers, and automatic turning machines | Broilers: 6-8 birds/㎡, Chickens: 5-6 birds/㎡ | Good animal welfare, reduced stress response, in-situ manure fermentation, lower environmental pressure |

| Aviary System | Layers (Welfare Breeding) | Slatted floor system + multi-layer wooden perches (layer height 0.8m, spacing 1.2m), configured with South African silos, Italian-imported feeding lines, vertical egg collection machines, and SIMENS ventilation equipment | Layers: 5-6 birds/㎡ | Meets animal welfare standards, high egg quality, natural breeding environment, high market acceptance |

Design of Core Automated Systems

Automated Feeding System

Configuration: 2 South African silos (20 tons each) + spiral conveyors (driven by MCN motors) + galvanized feed troughs/precise feeding lines + level sensors.

Process: Silo → Conveyor (frequency conversion control, conveying capacity 1.5 tons/hour) → Distributor → Cage feed troughs/floor feeding lines/aviary feeding points.

Automatic Control: Level sensors monitor feed residue in real-time; automatic refueling starts when feed is below 1/3 of trough capacity; feeding frequency can be set via APP (3 times/day for layers, 4 times/day for broilers), supporting customized feeding plans.

Automated Drinking System

Configuration: Stainless steel water storage tank (1 ton capacity) + booster pump + quartz sand filtration + UV disinfection device + DOSATRON medicator + 360° nipple drinkers/V-shaped water troughs.

Key Parameters: Drinker spacing (10cm/bird for layers, 8cm/bird for broilers), water pressure 0.15-0.2MPa, water supply ≥ 50ml/bird·minute; medicator enables precise chemical proportioning.

Automatic Control: Liquid level sensors link with booster pumps to maintain constant pressure; UV disinfection runs for 30 minutes every 2 hours; real-time monitoring of pH value and residual chlorine, with automatic alarm for abnormalities.

Intelligent Ventilation and Temperature Control System

Ventilation System: Longitudinal negative pressure ventilation (main) + horizontal natural ventilation (auxiliary), equipped with SIMENS fans (6 units, air volume 30,000m³/h) + automatic ventilation windows + roof ventilators.

Temperature Control System: 150mm-thick paper-aluminum composite frame cooling pads (reducing temperature by 5-8℃ when paired with fans) for summer; 15kW electric heaters for winter; additional local temperature sensors in aviary areas.

Control Targets: Temperature 18-25℃ (layers)/20-28℃ (broilers), humidity 50-70%, ammonia ≤ 15ppm, carbon dioxide ≤ 3000ppm; automatic adjustment of fan speed and ventilation window opening.

Automated Manure Cleaning System

Battery Cage Mode: Italian-imported 1.0mm HDPP manure belts (4 belts, 1.2m wide, speed 0.3m/s) + galvanized scrapers + manure conveying augers + manure collection tank.

Floor Rearing with Fermentation Bed Mode: 15m-span turning machines (automatically turning 1-2 times/day to keep litter loose).

Aviary System Mode: Scraper manure cleaners (timed operation) under slatted floors + manure dryers (reducing moisture to 12%-15% with low pollution emissions).

Environmental Treatment: Manure is temporarily stored in collection tanks, then processed via high-temperature composting (15-day maturation) or dryers, complying with GB 18596 discharge standards.

Automated Lighting and Egg Collection Systems (for Layers Only)

Lighting System: LED energy-saving lamps (3m spacing, 15W power, light intensity 30-50lux) + intelligent dimming controllers. Gradual light change in aviary areas to avoid stress.

Egg Collection System: Automatic egg collection belts (Italian material, service life ≥ 20 years) for cages. Vertical egg collection machines (efficiency 40,000 eggs/hour) + egg cleaning machines + grading machines (2,000-30,000 eggs/hour, customizable) for aviary systems.

Process: Eggs automatically roll onto collection belts → Cleaning → Grading → Boxing; breakage rate controlled within 1%.

Successful case from FamTECH

Contact us to customize your poultry farm.