Why Do You Need FamTECH’s Stainless Fermentation Tank?

Traditional windrow fermentation and trough fermentation have four major drawbacks: long fermentation cycle (10-20 days), large floor space (1,000 m² required for an annual output of 10,000 tons), low automation level (needing 3-5 operators), and poor production environment (difficulty in waste gas treatment), which severely restrict the industrial production of organic fertilizers.

The R&D team of FamTECH has innovatively developed the sealed organic fertilizer rapid fermentation tank, which completely solves the pain points of traditional processes. Besides fermentation tank, we also provide other manure handling machines for your poultry business: manure removal, manure dryer, manure pelletizer, manure dewater machine. The differences of FamTECH’s fermentation tank and traditional fermentation are as follows:

| Comparison Dimension | Traditional Fermentation | Performance of This Equipment |

| Fermentation Cycle | 10-20 days | 10 hours (rapid fermentation) |

| Floor Space (10,000 tons/year) | 1,000 m² | 30 m² (fermentation area only) |

| Number of Operators | 3-5 people | 1-2 people (automatic control) |

| Environmental Standard | Waste gas easily diffuses | Sealed treatment, 99% deodorization rate, waste gas spray purification |

| Applicable Environment | Greatly affected by seasons | Thermal insulation design, normal operation at below -20℃ |

| Service Life | No clear standard | Over 10 years (acid and alkali corrosion resistance) |

Details of FamTECH’s Stainless Steel Fermentation Tanks

The interior of the tank uses polyurethane as an insulation layer, which is less affected by the external environment. The entire process of feeding, fermentation, temperature-controlled drying and discharging is automatically controlled, ensuring fermentation throughout the year.

Sealed fermentation isolates odors, and no wastewater is generated during production, effectively solving environmental protection issues.

The organic fertilizer rapid fermentation equipment is all controlled by PLC programs, and all parts in contact with manure are made of stainless steel, which is corrosion-resistant and has a long service life.

Hydraulic drive is adopted, which has strong thrust. It can ensure the full-load operation of the decomposed materials in the tank, guarantee stable operation and low maintenance costs.

Customize Your Fermentation Tank

Fully Sealed Tank: Isolates temperature and humidity interference, meets industrial production standards, locks in waste gas to achieve zero secondary pollution.

Polyurethane Insulation Layer: Ensures stable fermentation all year round, saves energy and reduces consumption, accelerates production efficiency.

304 Stainless Steel Inner Wall: Corrosion-resistant and durable, extends equipment service life.

PLC Intelligent Control System: Dual modes of automatic + manual operation, easy to use and saves labor costs.

Three-Dimensional Space-Saving Design: Reduces land occupation and improves site utilization rate.

Full-Process Environmental Protection: Purifies waste gas to remove ammonia hazards, and the finished organic fertilizer enriches soil fertility, realizing green circulation.

Parameters of Stainless Steel Fermentation Tanks

| Model | Heating Power (kw) | Agitation Power (kw) | Agitation Speed (r/min) | Overall Dimensions (mm) |

|---|---|---|---|---|

| FMFT-5 | 4*6 | 7.5 | 3 | 220022005300 |

| FMFT-10 | 4*6 | 11 | 3 | 240024006900 |

| FMFT-20 | 8*6 | 18.5 | 3 | 370037008500 |

| FMFT-90 | 46 | 26.5 | 8-10 | 5000500010000 |

Sealed design

The tank adopts a fully enclosed design. The waste gas produced during fermentation is treated and discharged up to standard, without causing secondary pollution.

Heat insulation treatment

The tank body is treated with heat insulation to ensure fermentation throughout the year.

Vertical design

The tank adopts a vertical design, and the entire equipment occupies only 100 square meters.

Semi-permanent lifespan

The direct contact part between the tank body and the gearbox is made of 304 stainless steel, with a service life of up to 30 years.

Hydraulic drive

The tank body is hydraulically driven, featuring a simple structure, easy maintenance and low operating costs.

PLC control

The adoption of an electric PLC control system enables remote control.

Applicable Scenarios and Materials of Commercial Fermentation Tanks

- Applicable Entities: Large-scale breeding farms, circular agricultural bases, ecological agricultural projects, organic fertilizer production enterprises, etc..

- Processed Materials: Pig manure, chicken manure, cow manure, sheep manure, mushroom residue, crop straw, animal carcasses and other organic wastes.

- Application of Finished Products: Soil improvement, landscaping, crop planting, etc., realizing the resource utilization of organic wastes and contributing to sustainable development.

Advantages of Fermentation Tanks for Sale

Customization: Horizontal/vertical models and different capacity specifications can be customized according to customer needs.

Air-lift Design: No mechanical agitation impeller, low shear force, minimal damage to biological cells, especially suitable for organic material fermentation(mixing type is also optional).

Efficient Mass and Heat Transfer: High gas holdup and large gas-liquid contact area, leading to excellent oxygen dissolution rate and efficiency. Meanwhile, the rapid liquid circulation ensures good heat transfer effect, and heat exchangers can be installed on the external circulation pipeline for temperature control.

Sealing and Sterility: The tank has excellent sealing performance, can withstand pressure steam sterilization, and maintains positive pressure throughout the fermentation process, effectively avoiding contamination.

Flexibility and Convenience: Small volume, can be installed outdoors without the need for a separate workshop, equivalent to a mobile processing plant. Multiple units can be combined to improve processing capacity, adapting to needs of different scales.

Strong Adaptability of Strains: Aerobic strains can survive and reproduce at -25℃~80℃, and the beneficial bacterial community can efficiently kill harmful bacteria in raw materials.

Low Energy Consumption: Economical production power cost, high cost-effectiveness for long-term operation.

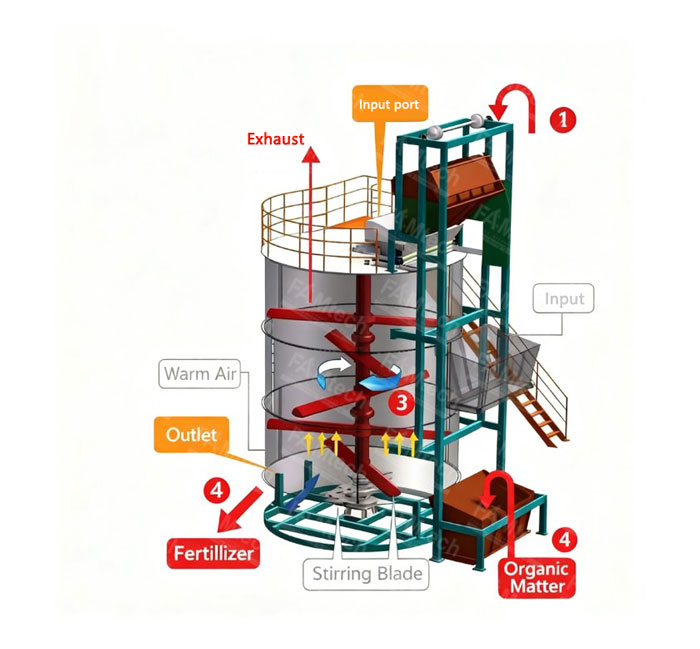

How Does Fermentation Tank Work?

Fermentation tank adopts the principle of aerobic fermentation, making use of the organic matter, residual protein, microorganisms, etc. in livestock and poultry manure. Under certain temperature, humidity and sufficient oxygen conditions, microorganisms take the organic matter and protein in the manure as food and multiply rapidly. They consume organic matter, protein and oxygen, and metabolize to produce ammonia, CO2 and water vapor.

At the same time, it releases a large amount of heat, raising the temperature inside the tank. At 45℃ to 60℃, it promotes the growth and metabolism of microorganisms. When the temperature is above 60℃, it can kill harmful bacteria, pathogens, parasite eggs and other harmful substances in the feces. At the same time, it balances the temperature, humidity and PH value for the survival of beneficial bacteria, meeting the survival conditions of beneficial bacteria and making them harmless. Thus, environmentally friendly organic fertilizers can be obtained, completely solving the problem of environmental pollution caused by manure and corpses. At the same time, they are treated harmlessly to become organic fertilizers, turning waste into treasure. Ensure the sustainable development of large-scale livestock farms.

Structure of the fermentation tank

Fermentation tank body: Stores and bears the fermentation process, with double-layer thermal insulation + three-layer structure, made of stainless steel with acid and alkali corrosion resistance

Stirring system: Motor, stirring shaft and blades, achieving material mixing and oxygenation.

Ventilation system: Filtration and sterilization, gas distribution and exhaust gas treatment, ensuring oxygen supply and exhaust gas emission;

Temperature control system: Steam or cooling water is passed through the jacket/coil to control the temperature inside the tank.

Detection and control system: pH, dissolved oxygen, and temperature sensors + automatic adjustment device to maintain a stable fermentation environment;

Auxiliary devices: Defoaming, sampling, online cleaning and other components, assisting in the process.

Operation and Maintenance Precautions

When the equipment is idle, it is necessary to carry out empty sterilization and drain all residual water in the tank, pipelines and jacket to avoid pressure deformation of the tank body or dilution of the culture solution.

During the cooling stage after empty sterilization and solid sterilization, negative pressure in the tank is strictly prohibited to prevent equipment damage or contamination.

In all operation links, the pressure in the air pipeline must be maintained higher than the tank pressure to avoid backflow of liquid in the tank and blockage of the filter element.