Manure pelletizer is a specialized equipment for converting chicken manure and other livestock and poultry manure (which can be combined with straw, sawdust and other auxiliary materials) into granular organic fertilizer after dehydration, fermentation, crushing and extrusion.

Manure pelletizer

Advantages of the manure pellet machine

Easy operation: High degree of automation simplifies the fecal treatment process and reduces labor costs.

Wide range of application scenarios: It can be used for self-use in small farms, large-scale organic fertilizer production and processing, or investment and entrepreneurship.

Environmentally friendly and efficient: Achieve harmless treatment of feces, turn waste into treasure, and meet the demands of green agriculture.

Why do you need chicken manure pellet machine in your poultry farm?

40% to 70% of the nutrients in chicken feed are excreted with manure, making chicken manure a high-quality organic fertilizer raw material rich in nutrients. However, direct application of chicken manure poses risks. The heat generated during fermentation can scorch the root systems of crops, and the pathogens it carries may also harm the crops.

The advantages of chicken manure pellet machine

Processed by a professional production line, it can remove harmful substances while retaining core nutrients.

Enhanced fertility, longer shelf life, and more convenient use.

The production cost is low, making it suitable for production, sale or investment in the industry.

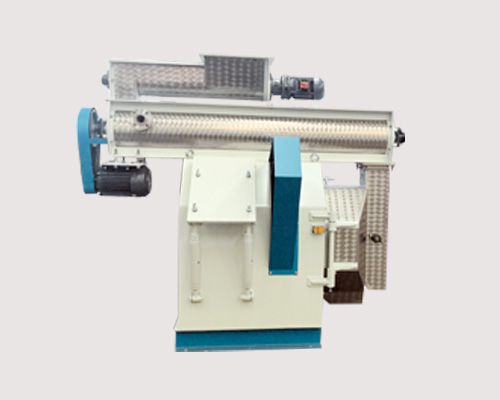

Flat die manure pelletizer

Production capacity: 0.8-5 tons per hour

Moisture content of raw materials: 12%-20%

Particle size: Adjustable from 2 to 10mm

Granulation rate: ≥95%, particle density ≥1.1g/cm³, moderate hardness

Motor power: 11-45kW

Mold life: The flat mold is made of alloy steel and undergoes carburizing treatment, with a service life of up to 3,000 to 5,000 hours

Core advantage

Simple structure and easy maintenance: Mold replacement is convenient and does not require professional tools. Daily cleaning can be completed in just 30 minutes.

Strong granulation adaptability: The pellet length can be flexibly adjusted to adapt to different fertilization scenarios.

Low-temperature granulation for nutrient protection: Utilizing a low-speed extrusion molding process, the material temperature during granulation is ≤60℃, effectively preserving the organic matter and microbial activity in manure. It is particularly suitable for the production of compound microbial fertilizers.

Suitable scenarios

Small and medium-sized high-end organic fertilizer factories, upgrading and transformation projects of family farms, for the production of characteristic organic fertilizers

Ring die manure pelletizer

Production capacity: 2-15 tons per hour

Moisture content of raw materials: 12%-18%

Particle size: Adjustable from 2 to 8mm

Granulation rate: ≥96%, particle density ≥1.2g/cm³, low hygroscopicity

Motor power: 37-110kW

Mold life: The ring mold is cast with wear-resistant alloy and its surface is treated with plasma spraying, with a service life of up to 5,000 to 8,000 hours

Core advantage

High yield, high efficiency and stability: The ring die and the pressure roller adopt line contact extrusion, with uniform force distribution. The single-machine production capacity is 1.5 to 2 times that of the flat die model, and it can operate continuously for 72 hours without failure.

Outstanding particle quality: The particle surface is smooth, with high density, not prone to moisture absorption and caking, and the storage period can be extended to more than 12 months, which is convenient for long-distance transportation and export.

Intelligent control is convenient: Equipped with a PLC control system, it can monitor parameters such as motor speed, particle temperature, and production capacity in real time, support remote fault diagnosis, and reduce the intensity of manual operation.

Suitable scenarios

It is suitable for large-scale high-end organic fertilizer factories and organic fertilizer projects of large-scale breeding groups. It is used to produce commercial organic fertilizers and compound microbial fertilizers that meet national standards, to meet the export and large-scale agricultural base procurement needs

Chicken manure pellet production line

FamTECH provides small, medium, large manure pellet production lines. Taking medium-sized production line as example:

A full-process automation solution covering pretreatment, pelleting, post-treatment and auxiliary systems to achieve efficient mass production.

Core configuration

Pretreatment: Continuous fermentation tank, belt filter press, double-shaft mixer, 100-mesh ultrafine crusher.

Granulation: Ring die manure pelletizer, return material conveyor.

Post-treatment: Counter-flow cooler, multi-layer vibrating screen, automatic film wrapping machine, 5-50kg adjustable fully automatic packaging line.

Auxiliary: PLC intelligent control system, central dust removal, equipment monitoring system.

Core advantage

The entire process is automated, and only 2-3 people are needed for monitoring, reducing labor costs by over 70%.

The product qualification rate is no less than 98%, the batch variation is no more than 3%, and the quality is stable.

Dust removal, wastewater and waste gas treatment are complete, and there is no risk of production suspension as environmental protection standards are met.

It is compatible with a variety of raw materials and product types, meeting diverse production demands.

Interlocking control saves energy by 15% to 25%, and the core equipment can operate without failure for ≥ 8,000 hours.

Details of FamTECH’s manure pelletizer

Grinding Chamber

The pressure roller and grinding disc are made of chrome-manganese steel, treated with high-temperature quenching.

Adjustment Nut

When adjusting the distance between the pressure roller and the grinding disc to make pellets, be sure to adjust the nuts on both sides evenly. This avoids damaging the pressure roller and grinding disc.

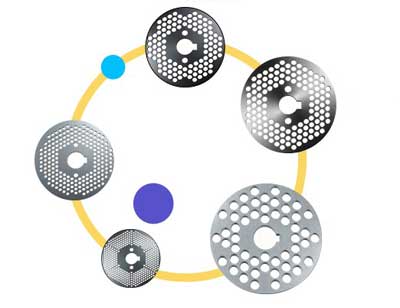

Multiple Aperture Options

Die holes: 3-8mm. The length, shortness, thickness of the discharged material can be controlled. For other sizes of grinding discs, please contact customer service for customization.

Pelleting progress of chicken manure

It takes 5 core steps to make granular fertilizer from chicken manure, with a clear and easy-to-operate process. We provide the equipment needed in every steps.

1. Pretreatment: Air-dry or oven-dry the chicken manure to reduce its moisture content to 55%-60%, and remove impurities such as stones and weeds.

2. Fermentation and decomposition: Mix chicken manure with auxiliary materials like straw and sawdust in proportion to adjust the carbon-nitrogen ratio. Pile up the mixture, turn it 2-3 times, and let it decompose for 7-15 days to kill pathogens and insect eggs.

3. Crushing: Feed the decomposed chicken manure into a crusher and grind it into fine powder to ensure good granulation effect.

4. Granulation: Send the crushed material into a granulator and make uniform granules through extrusion or granulation process.

5. Drying and cooling: Dry the wet granules until the moisture content is below 10%, then let them cool naturally to ensure the storage stability of the fertilizer.

Why choose FamTECH’s manure pellet machine

With over two decades of experience, we have assembled a high-quality R&D team and a dedicated service team, capable of providing comprehensive guidance from purchase to operation as soon as possible.

FamTECH attaches great importance to product quality. All the components of our manure pellet machine are made of high-quality alloy steel. The structure of the roller and the mold has been designed through multiple experiments to achieve the best compression ratio. The gearbox adopts high-precision gears to ensure long-term stable operation. FamTECH ‘s manure pellet machine outperforms its peers with its humanized design, reliable quality, high production capacity and low energy consumption.

All of our products strictly follow the ISO9001 international quality management system standards and have obtained CE certification and multiple national patents. We adhere to strict standards from steel procurement, production processes to assembly and warehousing.

We conduct three inspections during the production process, including self-inspection, random inspection and shipment inspection. Each manure pelletizer must be debugged before delivery so that it can be put into production upon customer receipt.